Índice

If you’re buying signage for a retail rollout, a chain refresh, or an OEM private-label program, you’re not really choosing “a sign.” You’re choosing maintenance load, brand consistency, and replacement risk. That’s why this acrylic vs. wood comparison matters.

Weather Resistance and Dimensional Stability

Acrylic wins when the environment isn’t friendly.

Acrylic doesn’t absorb moisture, so it stays more dimensionally stable. In real terms, that means fewer headaches like warping, swelling, edge lift, or cracked finishes when you mount signs near entrances, HVAC airflow, kitchens, or humid zones.

Wood can still work outdoors and in semi-outdoor storefronts, but it behaves like wood. It “moves.” If your install sites range from dry inland malls to coastal streets, you’ll see variation unless you spec the wood species, sealing, and finishing like you’re building furniture for a yacht.

Typical buyer pain point: the first batch looks great, then store #37 calls you about curling edges or peeling paint after weather swings. That’s not a “material problem.” That’s a spec + environment mismatch.

Maintenance and Daily Operations

This is where procurement teams quietly change their mind.

Acrylic signage usually needs simple cleaning. Staff can wipe it down during normal ops. Wood signage often needs more careful handling, plus periodic refinishing if you want it to look “new” instead of “vintage.”

Maintenance and Daily Ops: What changes on the floor?

- Acrylic: easier wipe-down routines, more predictable appearance over time

- Wood: needs a finish that can survive cleaners, grease, humidity, and fingerprints

If you run high-traffic spaces like supermarkets, convenience stores, salons, or quick-service restaurants, maintenance time is real money. It also affects NPS because a sign that looks tired makes the whole fixture look tired.

Outdoor Lifespan and Replacement Cycles

Wood signage lifespan can be long, but it’s not uniform. It depends on:

- wood species

- coating system

- UV exposure

- how often someone re-seals or re-paints

Acrylic signage lifespan is typically more predictable, especially when you spec UV-stable material and the right thickness and mounting method. That predictability matters when you’re planning a multi-store rollout with one PO and one install window.

Procurement-friendly takeaway: if you hate surprise replacements, acrylic is easier to standardize.

Brand Aesthetics and Visual Merchandising

This is the part marketing cares about, and they’re not wrong.

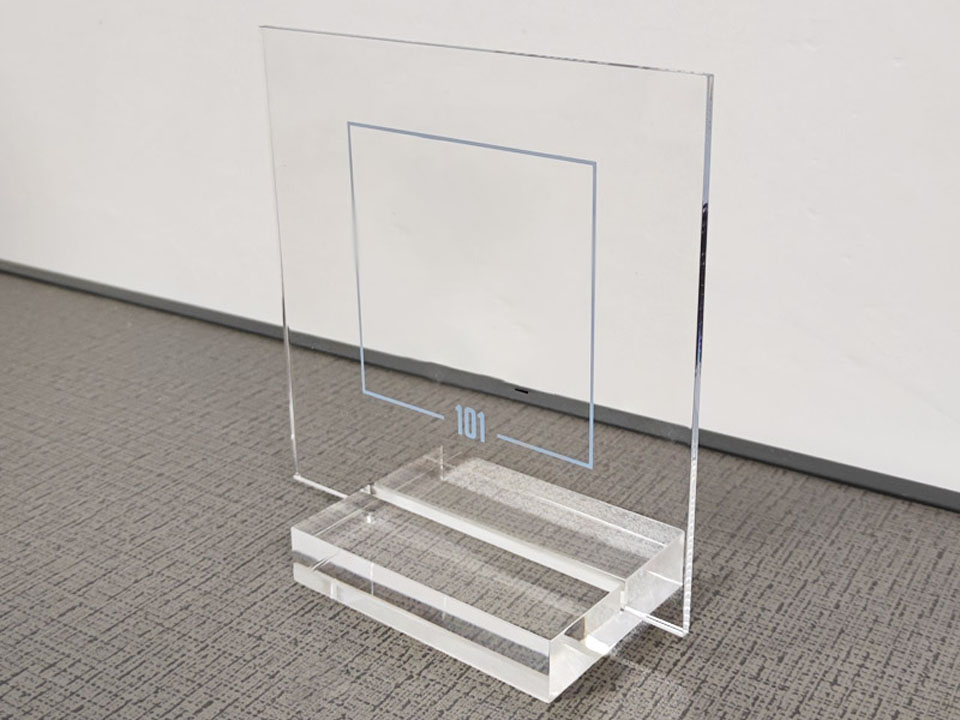

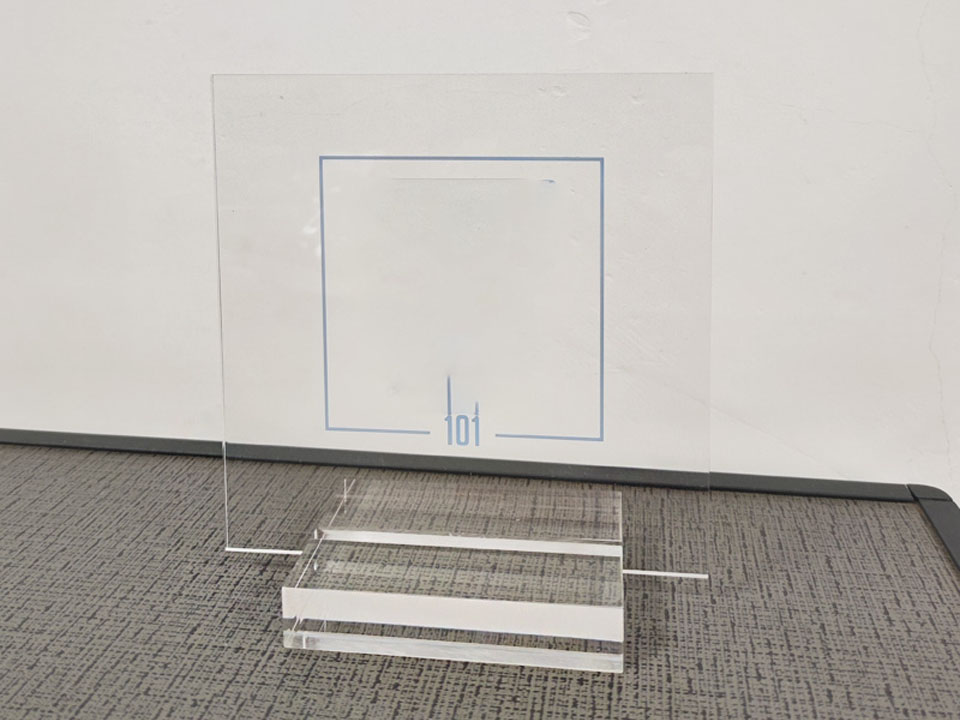

Acrylic reads as clean, modern, and premium—especially when you combine it with backlighting, edge lighting, standoffs, or layered construction. Wood reads warm, handmade, and craft-forward.

Brand Aesthetics: where each material fits

- Acrylic signs: beauty retail, electronics, clinics, modern boutiques, pop-ups, trade shows

- Wood signs: cafés, breweries, farm-to-table, rustic interiors, heritage-style storefronts

If your visual merchandising relies on crisp lines, high contrast logos, and consistent color, acrylic is usually the safer spec.

If your brand strategy is “human, cozy, and textured,” wood can be a strong choice, but you’ll want to plan for finish upkeep and color drift.

Batch Consistency and Multi-Store Rollouts

For B2B buyers, this section is the whole game.

When you order signage at scale, you’re not optimizing for one perfect sign. You’re optimizing for:

- repeatability across batches

- consistent color and logo geometry

- stable packaging and transit survival

- predictable install outcomes

Acrylic is typically better for batch consistency because it supports tighter control in cutting, polishing, printing, and assembly. Wood has natural variation even before you start finishing.

If you’ve ever managed a rollout where store managers “fix” signs locally, you already know the cost of inconsistency. You get mismatched tone, inconsistent fonts, and random substitutes that dilute the brand.

TSM note (real-world): if you care about chain-level uniformity, you need TSM-grade process control—tight tolerances, clear QC gates, and controlled color targets. That’s a manufacturing mindset, not a design preference.

Scratch, Dent, and Surface Aging

No material is magical. They fail differently.

Acrylic can scratch, especially in high-contact areas like door signage, queue rails, and checkout zones. Wood can dent, chip, and show edge wear fast if customers bump it with baskets or carts.

Surface aging: how to reduce risk

- For acrylic: consider protective films during installation, smarter placement, and finishes that match the abuse level

- For wood: spec harder topcoats, sealed edges, and avoid sharp corners where paint chips start

If the sign lives where customers touch it every day, plan for abrasion from day one. That’s how you avoid the “looks old in three months” complaint.

UV Stability and Yellowing Risk

Acrylic can yellow if you pick the wrong grade for UV exposure. That’s not a reason to avoid acrylic. It’s a reason to spec UV-stable material for outdoor or sunlit environments.

If your sign sits in a sunny window, under skylights, or on an exterior wall, write UV stability into the spec. Don’t assume “clear” stays clear by default.

Sustainability and Lifecycle Thinking

Sustainability isn’t just what the material is made of. It’s also how often you remake it.

Wood is renewable, and that’s a real advantage. But if the sign needs frequent refinishing or replacement to stay brand-clean, the lifecycle footprint can creep up.

Acrylic can make sense when it:

- lasts longer in the intended environment

- reduces redo cycles in rollouts

- supports consistent reuse across seasons (swap graphics, keep the structure)

If you’re a retailer running quarterly campaigns, a modular acrylic approach can reduce churn. Less churn means fewer emergency POs and fewer last-minute air shipments.

Comparison Table for B2B Sign Buyers

| Category | Sinais em acrílico | Traditional Wooden Signs | Why it matters for B2B rollouts |

|---|---|---|---|

| Weather resistance | Strong (doesn’t absorb moisture) | Variable (depends on sealing/finish) | Fewer site-to-site surprises |

| Dimensional stability | Elevado | Medium to low | Cleaner installs, less rework |

| Cleaning and upkeep | Easier routine cleaning | Needs more care, may need refinishing | Lower ops burden |

| Style direction | Modern, crisp, premium | Warm, craft, textured | Match brand positioning |

| Batch consistency | Strong | Natural variation | Brand uniformity across stores |

| Surface wear | Can scratch | Can chip/dent | Choose based on traffic/contact |

| UV risk | Manageable with UV-stable spec | Finish can fade or crack | Write material/finish into spec |

| Best-fit buying model | OEM/ODM, wholesale, repeat POs | Boutique, artisan, curated locations | Align with purchasing reality |

Practical Use Cases and Material Recommendations

| Cenário | What usually breaks first | Better pick | Spec note |

|---|---|---|---|

| Mall storefront logo wall | Dust + cleaning marks | Acrílico | Layered logo, standoffs |

| Street-facing outdoor sign | Moisture + sun | Acrílico | UV-stable + solid mounting |

| Coffee shop “menu vibe” wall | Edge chips, finish wear | Madeira | Strong topcoat + sealed edges |

| Cosmetics counter display signage | Fingerprints + brand precision | Acrílico | Crisp print + polished edges |

| Multi-store wayfinding system | Inconsistency across batches | Acrílico | Standardized CAD + QC gates |

| Seasonal pop-up / short campaign | Speed + clean install | Acrílico | Modular panels, easy swap |

Acrylic Fabrication for OEM/ODM and Wholesale Orders

If you’re sourcing as a retailer, distributor, or OEM client, you want a supplier that can handle spec discipline and volume without drama.

That’s exactly how we operate at Fabricante de fabrico de acrílico na China—custom, bulk, OEM/ODM, and repeatable production runs.

Here are the most direct paths depending on what you’re building:

- Start with sinais acrílicos personalizados for branded signage systems and store rollouts.

- If your sign design needs strict clarity, thickness options, or special finishes, check chapas acrílicas personalizadas.

- If your project is more like retail fixtures and merchandising, pair signage with expositores acrílicos personalizados.

- If you want the process details, see fabrico de acrílico and how we handle cut/print/assemble workflows.

- If you’re collecting specs for a PO, use como personalizar to align files, finish, and packaging early.

- If you need supplier confidence for repeat orders, review controlo de qualidade—this is where “TSM-grade” consistency is built.

- When you’re ready to quote or align on MOQ and lead time, hit contacto.

Final Take

Pick wood when your brand story needs warmth and texture, and you’re okay managing finish maintenance like an ongoing asset.

Pick acrylic when you need repeatable quality, cleaner operations, and rollout-friendly consistency—especially for B2B buyers who live in POs, planograms, and tight launch windows.

If you want, I can turn this into a conversion-focused version for your site that keeps the same keyword headings, adds a tighter CTA flow, and rebalances for your top buyer personas (retailers, distributors, and OEM clients).