Se lavorate con confezioni al dettaglio, set regalo o kit cosmetici, vedete già l'acrilico ogni giorno. Si trova sopra la scatola di carta come finestra trasparente, diventa un espositore da banco vicino alla cassa o si trasforma in un trofeo per una campagna VIP. Quando si capisce come viene prodotto l'acrilico, si possono fare scelte di packaging migliori e si evitano molte dolorose rielaborazioni.

Di seguito illustriamo il processo di produzione dell'acrilico, per poi ricollegarlo a scenari reali del marchio e al modo in cui Zhibang supporta i vostri progetti.

Indice dei contenuti

Cos'è l'acrilico e perché i marchi lo usano

L'acrilico, spesso chiamato PMMA, è una plastica trasparente utilizzata per finestre, coperchi, vassoi e espositori. Rispetto alla normale plastica, offre:

- Elevata chiarezza per la presentazione del prodotto

- Buona resistenza ai graffi e ai raggi UV

- Prestazioni stabili nell'illuminazione dei negozi

Per un marchio di bellezza, questo può significare un imballaggio personalizzato in cui la scatola di carta fa il branding e la vetrina o l'espositore in acrilico attira l'attenzione dell'acquirente in due secondi.

Vedete l'acrilico insieme a scatole regalo in carta, espositori in cartone e imballaggio in tubo di carta, soprattutto quando un prodotto ha bisogno di una narrazione “trasparente”.

Materie prime acriliche: Dal monomero al PMMA

La storia dell'acrilico inizia con un monomero liquido chiamato MMA (metacrilato di metile). I fornitori di prodotti chimici producono l'MMA a partire da prodotti chimici di base come l'acetone e il metanolo. La parte importante per voi non è la formula, ma il controllo:

- La purezza del monomero determina il grado di trasparenza del foglio finale

- Gli additivi controllano la stabilità ai raggi UV, la resistenza agli urti e il colore.

- Le impurità sbagliate possono causare ingiallimenti o cricche da stress in un secondo momento.

Per i proprietari e gli acquirenti del marchio, questo è il punto in cui la “qualità” conta davvero. Un acrilico più economico e di bassa qualità può sembrare buono nel primo campione, ma sotto la luce del negozio per 12 mesi può iniziare a sembrare un po' torbido.

Polimerizzazione: Come viene creata la resina acrilica

La fase successiva è la polimerizzazione. Il monomero MMA si lega in lunghe catene e diventa resina PMMA. Questa reazione può avvenire in modi diversi, ma i punti chiave sono:

- La temperatura e il tempo controllano il peso molecolare

- Il peso molecolare influisce sulla fluidità durante la lavorazione e sulla resistenza agli urti

- Vengono aggiunti stabilizzatori per evitare che il materiale si degradi nelle fasi successive di riscaldamento.

Considerate questa fase come la “definizione del DNA” dell'acrilico. Se la polimerizzazione non è stabile, è possibile che si verifichino deformazioni, bolle o microfratture durante la termoformatura di un coperchio o di un espositore POS. A volte gli acquirenti si accorgono di questo problema solo dopo un ordine di massa, cioè molto tardi.

Processo di produzione dello strato acrilico fuso

Uno dei percorsi principali è l'acrilico colato. Funziona così:

- Miscelare monomero, catalizzatore e additivi in uno sciroppo

- Versare il tutto in uno stampo tra due lastre di vetro.

- Sigillare i bordi e inviare il “sandwich” in forno o in autoclave.

- Riscaldare e curare lentamente fino a quando lo sciroppo non diventa una lastra solida.

- Raffreddare, rimuovere il vetro, rifinire i bordi, talvolta lucidare o applicare una pellicola protettiva.

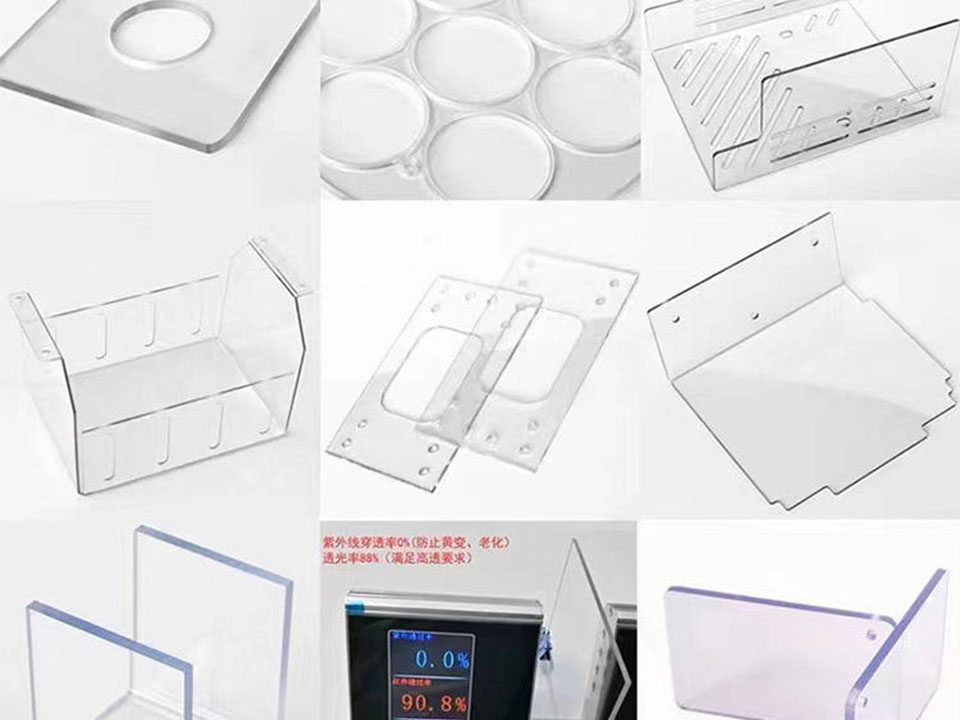

Proprietà dello strato acrilico fuso

Poiché il materiale polimerizza all'interno dello stampo, le lastre acriliche colate hanno di solito un'alta percentuale di umidità:

- Elevata chiarezza ottica

- Minore stress interno

- Opzioni di lastre spesse (per espositori o mobili pesanti)

- Buone prestazioni per la lavorazione e l'incisione CNC

Per un profumo di alta qualità in un set rigido scatola regalo in carta kraft, L'acrilico colato è una buona scelta se avete bisogno di un coperchio o di uno zoccolo spesso e simile al cristallo sotto la bottiglia. Il pezzo è simile al vetro ma pesa meno e può essere colorato per adattarsi al tono del vostro marchio.

Una piccola parte grammaticale, forse non perfetta, ma rende l'idea.

Processo di produzione delle lastre acriliche estruse

L'altra via comune è l'acrilico estruso. I passaggi sono diversi:

- In primo luogo, il PMMA si presenta sotto forma di pellet solidi

- I pellet entrano in un estrusore e vengono riscaldati fino alla fusione.

- La colata scorre attraverso una matrice piatta per formare un foglio continuo.

- I rulli impostano lo spessore e la consistenza della superficie

- Il foglio si raffredda, quindi viene tagliato a misura e confezionato.

Caratteristiche dello strato acrilico estruso

Poiché il processo è continuo, le lastre estruse offrono altri vantaggi:

- Migliore tolleranza di spessore su tutta la lastra

- Maggiore produzione, prezzo più conveniente per progetti di grandi dimensioni

- Buone prestazioni nella termoformatura e nella piegatura semplice

- Ideale per finestre e cassonetti luminosi di spessore standard

Per un grande lancio di un e-commerce transfrontaliero o di una catena di supermercati, l'acrilico estruso è di solito il materiale preferito. Consente di ridurre il costo unitario dell'imballaggio senza compromettere la visibilità sullo scaffale.

Tabella di confronto: Strato acrilico colato o estruso

Potete utilizzare questa tabella quando parlate con il vostro team o con i fornitori:

| Aspetto | Lastra acrilica fusa | Lastra acrilica estrusa |

|---|---|---|

| Processo | Monomero liquido colato tra i vetri, polimerizzato in batch | Pellet di PMMA fusi e spinti attraverso una matrice |

| Modalità di produzione | Produzione in lotti, flessibile per piccole tirature | Produzione continua, ideale per grandi volumi |

| Gamma di spessori | Può essere molto spesso, più dimensioni personalizzate | Gamma di spessori standard, ottima per lastre piane |

| Qualità ottica | Chiarezza molto elevata, basso stress interno | Leggermente più stress interno, ancora chiaro |

| Comportamento di lavorazione | Ottimo per CNC, incisione, finitura di alto livello | Ottimo per il taglio e la termoformatura |

| Controllo della tolleranza | Buono, ma con maggiori variazioni da foglio a foglio | Tolleranza di spessore molto ridotta |

| Utilizzo tipico | Espositori di fascia alta, premi, coperchi pesanti | Finestre, light box, espositori per il mercato di massa |

Non è necessario copiare la tabella parola per parola; potete anche adattare il vocabolario alla voce del vostro marchio.

Controllo di qualità e prestazioni delle lastre acriliche

Indipendentemente dal processo scelto, i fornitori seri eseguiranno il controllo qualità:

- Spessore e planarità

- Trasmissione della luce e foschia

- Coerenza del colore nel lotto

- Sollecitazione interna (verificata con lente polarizzante)

- Prestazioni di impatto e flessione

- Difetti superficiali come bolle o punti neri

Per i progetti di packaging, due punti dolenti si ripresentano continuamente:

- Disadattamento del colore e della lucentezza Coperchio in acrilico, scatola di carta e inserto stampato devono sembrare un'unica famiglia. Noi di Zhibang abbiniamo il pezzo in acrilico al vostro servizi di stampa in modo che il Pantone, la lamina e la vernice parlino insieme, non si contrastino.

- Accumulo di tolleranze Se lo spessore o le dimensioni dell'acrilico sono sbagliate, non si adatterà bene all'ambiente. scatole regalo in carta personalizzate o scatole per extension per capelli. Consideriamo l'intera struttura della confezione, non solo una parte allentata, per ridurre il rischio di inceppamento sulla linea di riempimento.

A volte i clienti pensano solo alle opere d'arte e dimenticano questi numeri “noiosi”. In seguito, la finestra fa rumore o il vassoio non si blocca. Ecco perché il controllo di qualità delle lastre acriliche non serve solo per i rapporti di fabbrica, ma anche per la vostra esperienza sullo scaffale.

Come la produzione di acrilico influisce sugli scenari reali dell'imballaggio

Vediamo come questo processo si adatta al vostro lavoro quotidiano.

- Set per la bellezza e la cura della pelle Un blocco acrilico fuso sotto una bottiglia di siero in una scatola rigida può aiutare il vostro prodotto a distinguersi in uno scaffale affollato. Se il PMMA è prodotto con una polimerizzazione stabile, rimarrà chiaro anche sotto la forte luce del negozio.

- Confezioni regalo e stagionali Finestre in acrilico estruso combinate con sacchetti regalo di carta o imballaggio in tubo di carta per dare agli acquirenti una rapida anteprima del regalo senza aprirlo. Lo spessore stabile facilita la progettazione della finestra fustellata e riduce gli sprechi in linea.

- Espositori per la vendita al dettaglio e unità POS Le strutture in cartone e le facce in acrilico sono comuni per le isole espositive. La scelta tra colato ed estruso influisce sulla resistenza agli urti, sul comportamento ai graffi e anche sul modo in cui progettiamo la struttura. espositori in cartone sotto.

Quando gli acquirenti chiedono “perché il costo di questo acrilico è diverso da quello dell'altro”, di solito la risposta non è solo lo spessore, ma l'intera catena, dal monomero alla lastra, e il modo in cui si adatta alla storia del vostro marchio e al livello di rischio.

Lavorate con Zhibang per i progetti di acrilico e imballaggio

Zhibang Packaging non è una fabbrica di acrilico grezzo, ma integra le parti in acrilico in soluzioni di imballaggio complete. Il nostro team collabora con marchi di vendita al dettaglio, fabbriche OEM/ODM, venditori di e-commerce transfrontalieri, grossisti, agenzie di design e aziende di articoli da regalo per bilanciare:

- Scelta del materiale (fuso o estruso)

- Effetto scaffale e sensazione di unboxing

- MOQ, tempi di consegna e rischio della catena di fornitura

- Sistema di confezionamento: scatola + inserto + finestra o espositore in acrilico

Poiché ci occupiamo sia della confezione in carta che della parte in acrilico, parlate con un unico team invece che con tre fornitori diversi. Questo rende il progetto un po' più semplice, anche quando il briefing è inizialmente complicato.

Se progettate una nuova confezione regalo, un kit cosmetico o un espositore con elementi in acrilico, potete sempre partire da un'idea semplice e lasciare che i nostri ingegneri la traducano in struttura, materiale e specifiche di stampa. Voi vi concentrate sul vostro marchio, noi ci occupiamo dei noiosi ma importanti dettagli di produzione.