Summary

UV Printing for Full-Color Acrylic Customization is a modern printing technology that utilizes ultraviolet light to cure ink on various substrates, particularly acrylic, resulting in vibrant, durable, and high-quality prints. Developed in the early 2000s, UV printing emerged as a solution to the limitations of traditional printing methods, such as long drying times and material compatibility issues. Its rapid curing process allows for quick production, making it particularly advantageous for industries requiring customized and on-demand products, such as signage, branding, and personalized gifts.

Table of Contents

This technology has become increasingly notable for its versatility, enabling high resolution printing on a range of materials, including plastics, wood, and metals. UV printing is especially popular in the acrylic market, where its ability to produce striking visual effects has transformed applications in interior design, marketing, and consumer goods. The technique has gained traction in various sectors due to its cost-effectiveness for short-run productions and the growing demand for eco-friendly manufacturing processes, as it produces minimal waste and does not release volatile organic compounds (VOCs) during printing.

However, UV printing is not without its challenges. Initial equipment costs can be significant, and the technology can lead to increased wear and tear on printing machinery. Additionally, users must navigate the limited working time for UV inks, which can complicate the printing process. Despite these concerns, the benefits of UV printing—such as its quick turnaround, vibrant color reproduction, and environmental advantages—have solidified its status as a preferred method for full-color acrylic customization.

As the industry continues to evolve, trends such as sustainability initiatives, market expansion into new sectors, and technological advancements are expected to shape the future of UV printing. These developments promise to enhance the capabilities and applications of UV printing, making it an increasingly integral component of modern manufacturing and design.

History of UV Printing

UV printing, which utilizes ultraviolet light to cure ink instantly on various substrates, emerged as a transformative technology in the early 2000s. This innovative method was developed to address the limitations of traditional printing techniques, particularly the drying time and material compatibility issues. By integrating UV light into the printing process, UV printers enabled quick production times and vibrant, durable prints that could adhere to a wide range of materials, including plastic, acrylic, wood, and metal. The evolution of UV printing began with advancements in ink formulation, leading to the creation of UV curable inks that offer superior adhesion and weather resistance. This marked a significant departure from conventional methods that relied on heat drying, allowing for immediate curing of inks upon application. As a result, businesses could produce high-quality prints without the extended waiting periods typically associated with traditional drying methods, thereby enhancing operational efficiency and reducing lead times. By 2024, UV printing had gained traction in various industries due to its cost-effectiveness for short-run productions and the ability to create custom, on-demand items quickly. The technology has continued to evolve, leading to innovative applications such as 3D printing enhancements and the creation of tactile textures. Today, UV printing is recognized for its versatility and high-quality output, making it a preferred choice for many businesses looking to meet modern printing demands.

Process of UV Printing

UV printing is a distinctive digital printing technique that utilizes ultraviolet light to cure or dry UV ink almost instantaneously upon application to a substrate. This process involves several key steps that differentiate it from traditional printing methods, enhancing its efficiency and versatility across various materials.

How UV Printing Works

The UV printing process begins with the preparation of the desired image on a computer. Once the design is finalized, the image is converted into a suitable format using Raster Image Processing (RIP) software. The substrate, which can range from acrylic and paper to metal and foam board, is then cleaned to ensure optimal ink adhesion. After preparing the substrate, it is placed on the bed of the UV printer. The printer uses high-intensity UV lamps to instantly cure the specially formulated UV inks as they are applied. As the ink is printed onto the substrate, the UV lights immediately activate, polymerizing the ink and forming a hard, durable coating that adheres tightly to the surface. This rapid curing process minimizes drying time, allowing for high-quality prints that are vibrant and detailed, with no risk of smudging or spreading.

Advantages of UV Printing

One of the major benefits of UV printing is its ability to print on a wide variety of materials without the need for additional processes such as heat pressing or weeding. The UV-curable inks are designed to be weather-resistant, making them suitable for outdoor applications such as signage and branding on acrylic products. This capability ensures that the prints maintain their quality and vibrancy under various environmental conditions. Moreover, UV printing contributes to eco-friendliness in the manufacturing process. The absence of volatile organic compounds (VOCs) and odors during the printing process makes it a more sustainable option compared to traditional printing methods. This is particularly important in industries where environmental impact is a concern.

Customization and Production Efficiency

The UV printing process is particularly beneficial for small businesses and operations looking to create customized, limited-run products. Its quick turnaround time allows businesses to meet niche market demands effectively, producing items such as promotional products, packaging, and industrial printing. Additionally, the technology’s adaptability to various substrates enables businesses to expand their product offerings without relying on external vendors, leading to increased revenue opportunities.

Applications of UV Printing in Acrylic Customization

UV printing on acrylic has revolutionized various industries by providing high-quality, vibrant prints that enhance the aesthetic and functional value of products. The technology is utilized across multiple sectors, demonstrating its versatility and effectiveness.

Signage and Displays

One of the primary applications of UV printing on acrylic is in the signage and display industry. Businesses frequently use UV-printed acrylic for creating visually striking signs that are both durable and weather-resistant. These signs maintain their quality over time and are suitable for a range of environments, from storefronts to trade shows and exhibitions. Popular uses include storefront signs, directional signage, and promotional display panels, all designed to attract attention and convey messages effectively.

Interior Design

In interior design, UV-printed acrylic plays a significant role in enhancing spaces with modern and elegant elements. Custom-printed acrylic panels, wall art, and decorative pieces add a sophisticated touch to both residential and commercial settings. This application enables designers to create unique aesthetic experiences that reflect individual styles, making UV-printed acrylic a preferred choice for home décor and commercial projects alike.

Branding and Marketing

UV printing offers businesses a powerful tool for branding and marketing efforts. Customized acrylic signage, promotional displays, and product packaging allow companies to reinforce their brand identity while creating memorable experiences for customers. The ability to print intricate designs and logos on acrylic surfaces provides high levels of customization that meet specific promotional needs.

Personalized Gifts and Awards

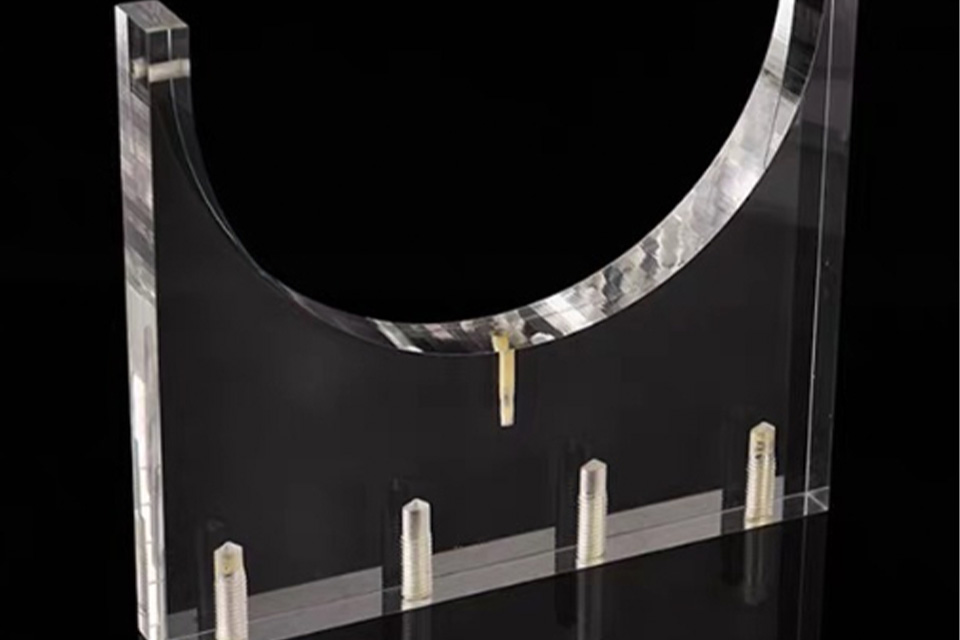

Another notable application of UV printing on acrylic is in the creation of personalized gifts and awards. This technology allows for the printing of custom designs, photographs, and messages onto acrylic products such as trophies, plaques, and keepsakes. The vibrant colors and clarity of the prints add an elegant touch, making UV-printed acrylic a popular choice for commemorative items and special occasion gifts.

Consumer Goods

The consumer goods sector also benefits from UV printing on acrylic. Common applications include creating personalized merchandise like keychains, phone cases, and acrylic desk calendars. The ability to produce high-resolution images and unique designs caters to the growing demand for customized products, enabling businesses to offer distinct items that resonate with consumers.

Industrial and Commercial Uses

In industrial settings, UV printing is utilized for creating control panels, equipment nameplates, and signage. The durability and precision of UV-printed acrylic make it ideal for products that require resilience to environmental factors and high visibility. Additionally, the technology supports the production of protective shields, such as sneeze guards and barriers, which gained prominence in the post-COVID landscape.

Advantages of UV Printing for Acrylic

UV printing on acrylic offers a multitude of benefits, making it an increasingly popular choice for various applications, including signage, awards, and decorative items. This method utilizes ultraviolet (UV) light to cure inks instantly, providing superior print quality and durability compared to traditional printing techniques.

Key Benefits

1. Vibrant Color Reproduction

One of the most significant advantages of UV printing on acrylic is its ability to produce vibrant colors with exceptional clarity and depth. The UV-curable inks adhere seamlessly to the acrylic surface, resulting in stunning, long-lasting prints that capture the viewer’s attention.

2. Durability

Acrylic printed with UV technology is highly resistant to impact, weathering, and UV radiation. This durability makes it suitable for both indoor and outdoor applications, ensuring that prints maintain their quality over time, even in challenging environmental conditions. The inherent strength of acrylic fiber ensures longevity, with UV prints retaining their vibrancy despite prolonged exposure to sunlight.

3. Versatility

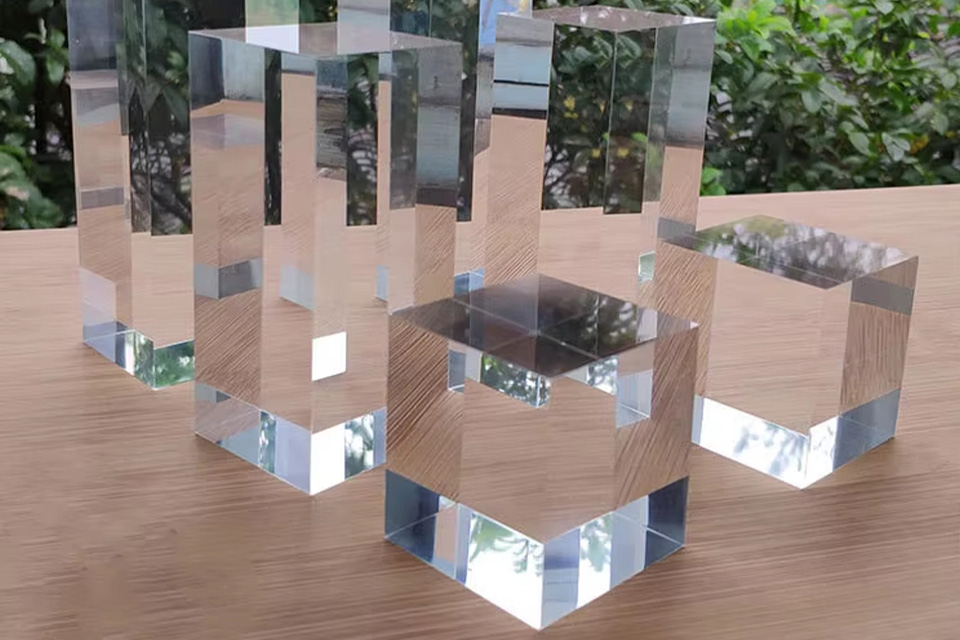

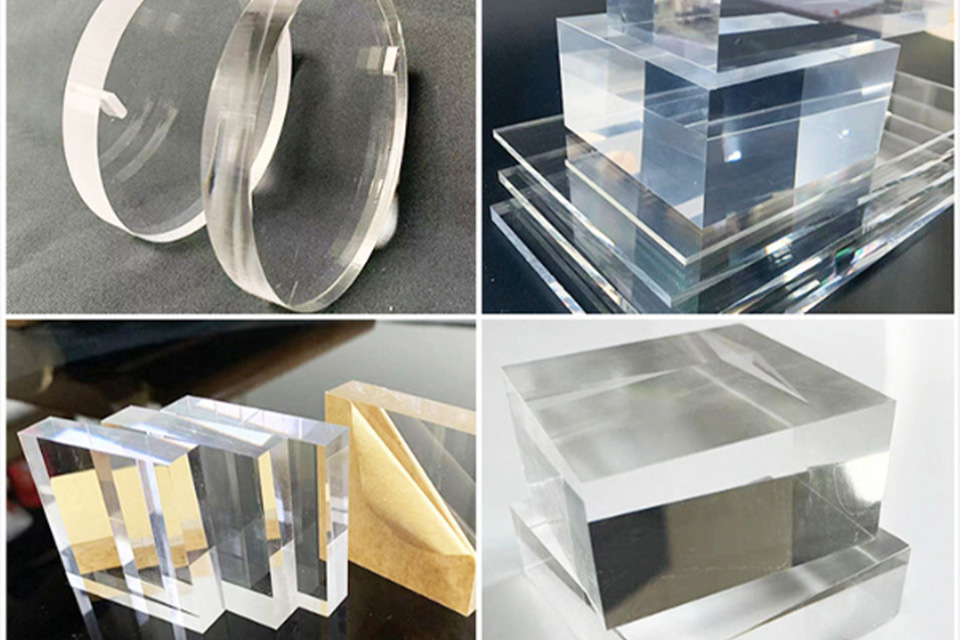

UV printing on acrylic is incredibly versatile. It can be applied to a wide range of acrylic substrates, including clear, colored, and textured surfaces. Acrylic is also available in various thicknesses and sizes, allowing for extensive customization options. This versatility extends to the types of products that can be created, from signage to packaging and decorative pieces.

4. Quick Turnaround

Unlike traditional printing methods that require longer setup times and drying periods, UV printing offers faster production times due to its immediate curing capabilities. This efficiency is particularly beneficial for businesses that need to fulfill orders quickly, allowing for customized and on-demand printing without compromising quality.

5. Eco-Friendly Process

UV printing is considered an environmentally friendly option, as it produces zero volatile organic compounds (VOCs) and minimal waste during the printing process. This aligns well with the growing demand for sustainable practices in manufacturing and printing.

6. High-Resolution Outputs

The advanced UV curing process results in high-definition prints with crisp details and improved gloss levels, meeting the high-quality standards expected in professional applications. This enhanced print quality is particularly important for designs requiring intricate details and vibrant color fidelity.

Challenges and Limitations

Despite the advantages of UV printing for full-color acrylic customization, there are notable challenges and limitations that users must consider.

Cost Considerations

While UV printing can be cost-effective in terms of material usage and production time, the initial investment for UV printing equipment can be substantial, particularly for small businesses. The economic feasibility may be questioned if the projected returns do not justify the upfront costs, especially for operations with limited budgets.

Short Working Time

One of the significant drawbacks of UV printing is the limited working time for emulsion on press, which is notably shorter compared to conventional inks. This can pose difficulties for press operators, as maintaining proper ink and water balance becomes critical, complicating the printing process.

Equipment Wear

UV inks can lead to increased wear and tear on printing equipment, such as blankets, rollers, and plates. The rapid curing process, while advantageous for efficiency, can contribute to more frequent maintenance needs and potential replacement of parts, ultimately raising operational costs.

Scratch Sensitivity

Acrylic materials, including PMMA used in UV printing, are susceptible to scratches, which can compromise the aesthetic quality of printed products. To address this issue, additional coatings or treatments may be necessary to enhance scratch resistance, adding to the complexity and cost of the final product.

Environmental Concerns

Although UV printing technology offers certain environmental advantages, such as lower VOC emissions compared to solvent-based inks, it still contributes to car- bon emissions from electricity usage. The balance between sustainability and economic viability continues to be a concern for many businesses looking to adopt this technology.

Production Limitations

The versatility of UV printing is sometimes hampered by the need for specific equipment compatibility and limitations in handling various materials. Users must ensure their systems are equipped to manage the size and type of acrylic they intend to print on, which may restrict operational flexibility.

Future Trends in UV Printing

The UV printing industry is poised for significant advancements and trends that are expected to shape its future landscape. As technology evolves, several key areas are emerging that promise to enhance the capabilities and applications of UV printing.

Sustainability Initiatives

Sustainability is increasingly becoming a driving factor in the UV printing sector, with a growing emphasis on eco-friendly solutions. By 2024, there is a concerted push towards using environmentally friendly inks derived from organic compounds, which are free from hazardous chemicals and solvents. Additionally, UV LED printers are gaining popularity due to their reduced energy consumption, contributing to a lower carbon footprint that aligns with global sustainability goals. This shift not only appeals to environmentally conscious consumers but also helps businesses reduce their environmental impact.

Market Expansion and Innovative Applications

As UV printing technology continues to advance, new and innovative applications are emerging, expanding the market potential. Industries ranging from fashion and textiles to automotive and aerospace are beginning to recognize the versatility of UV printing. Notably, advancements in 3D printing enhancements and the ability to create tactile textures and embossing effects are broadening the scope of what can be achieved with UV printing. This trend is expected to drive market expansion, attracting more businesses to adopt UV printing for a variety of applications.

Cost-Effectiveness and Efficiency

Another significant trend is the cost-effectiveness of UV printing for short-run productions. In 2024, this advantage is further amplified by advancements in print speed and efficiency, enabling businesses to produce small batches of high-quality prints quickly and affordably. This capability caters to the growing demand for on-demand printing and reduces the need for extensive inventory storage, which is particularly advantageous for small businesses and startups.

Technological Advancements

The ongoing development of UV printing technologies is set to enhance the user experience and operational efficiency. Modern UV printers are becoming more user-friendly, featuring intuitive controls that cater to non-specialists. Furthermore, advancements in UV ink formulations are improving the quality and durability of prints, making them more resistant to weather elements and everyday wear and tear. These technological enhancements will likely attract more businesses to invest in UV printing capabilities.