Summary

Acrylic product manufacturing encompasses the processes involved in creating items from acrylic materials, notable for their clarity, durability, and versatility. As industries increasingly demand custom acrylic solutions, manufacturers face various challenges that threaten production efficiency, cost-effectiveness, and environmental sustainability. Notable obstacles include rising raw material costs, stringent technical requirements, and growing competition from alternative materials, which collectively impact the industry’s ability to meet consumer expectations and maintain competitive advantage.

Table of Contents

The volatility of raw material prices, particularly for petrochemical-derived components like acrylic acid, poses significant financial pressures, especially on smaller manufacturers who may struggle to absorb these fluctuations. Additionally, the intricate production processes necessitate skilled craftsmanship and advanced technology, making it imperative for manufacturers to invest in talent and equipment to uphold quality standards. Environmental concerns further complicate matters, with increased scrutiny on waste management and pollution prompting the industry to explore sustainable practices and innovative recycling methods.

On the other hand, the acrylic manufacturing sector is also witnessing opportunities for growth driven by advancements in technology and changing consumer demands. The integration of smart technologies, such as automation and IoT, is revolutionizing production efficiency while reducing operational costs. Concurrently, the trend to- wards customization is pushing manufacturers to adopt digital fabrication techniques, enabling rapid production of bespoke products that meet specific client needs.

Furthermore, strategic market expansion into emerging regions presents a significant opportunity for acrylic manufacturers to tap into new consumer bases while adapting their offerings to align with local market trends. As the industry continues to navigate these challenges and embrace innovations, the future of acrylic manufacturing appears poised for transformation, characterized by a focus on sustainability and enhanced product offerings in response to evolving market demands.

Challenges in Acrylic Product Manufacturing

Acrylic product manufacturing faces several significant challenges that impact pro- duction efficiency, cost-effectiveness, and sustainability. As the demand for acrylic products continues to grow, manufacturers must navigate these obstacles to maintain competitiveness and meet customer expectations. Material and Production Costs

One of the foremost challenges is the volatility in raw material prices, particularly for petrochemical-derived inputs like acrylic acid and butyl acrylate. Supply chain disruptions, geopolitical instability, and fluctuating energy costs contribute to price instability, exerting pressure on production costs and profit margins. Smaller manufacturer may struggle to absorb these costs, leading to disparities in competitive capabilities.

Technical and Process Requirements

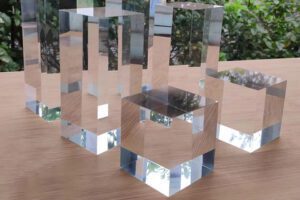

The production technology for acrylic products involves high technical requirements across several key processes, including material selection, design, and processing techniques. For instance, the fabrication of small acrylic display boxes necessitates precise design specifications, requiring in-depth knowledge of material properties and skilled craftsmanship. Each step—ranging from cutting and grinding to hot bending and bonding—demands skilled technicians and advanced equipment to ensure quality and market value.

Environmental Concerns

Sustainability presents both challenges and opportunities for acrylic manufacturers. While there is a declining need for new product manufacturing, the focus on reducing landfill waste and pollution is critical. This includes the development of bio-based PMMA and innovations in recycling processes, which can be complex and costly to implement. Moreover, managing the waste produced from manufacturing processes and 3D printing technologies poses additional environmental challenges, necessitating effective waste management solutions.

Competition from Alternative Materials

The market is increasingly threatened by substitutes, such as bio-based and hybrid binder systems, which are emerging as sustainable alternatives to tradition- al acrylics. This fragmentation can lead to market cannibalization, where new materials directly compete with established acrylic products. Manufacturers must continuously innovate and adapt to these changes while meeting rising customer expectations for performance, cost-effectiveness, and environmental sustainability.

Customization and Market Demands

The growing demand for customized acrylic products adds another layer of complexity to manufacturing processes. Companies must be agile in responding to specific customer needs while maintaining efficient production timelines. This often involves intricate communication with customers to ensure that their requirements are accurately met and that production schedules align with market demand. The challenge is to balance customization with efficiency without compromising quality or increasing costs excessively. By addressing these challenges, acrylic manufacturers can explore new opportunities for growth and innovation while enhancing their operational efficiency and sustainability practices.

Opportunities in Acrylic Product Manufacturing

Integration of Smart Technologies

The acrylic manufacturing industry is experiencing a significant shift towards the adoption of smart technologies, which are poised to revolutionize production processes. The integration of automation and robotics enables manufacturers to enhance production efficiency, reduce human error, and streamline operations. Robotic systems are capable of executing tasks such as cutting, shaping, and assembling acrylic products with high precision, allowing for continuous operation and cost reduction in labor. Furthermore, Internet of Things (IoT) technologies facilitate real-time monitoring and control of production lines, enhancing operational oversight and minimizing downtime through proactive issue identification.

Sustainable Practices and Material Innovations

As global environmental concerns rise, acrylic manufacturing is moving towards more sustainable practices. Innovations such as bio-based acrylics, derived from renew- able resources, present a promising alternative to traditional petroleum-based mate- rials. The development of processes aimed at recycling poly (methyl methacrylate) (PMMA) and reducing energy consumption during production are essential to aligning with sustainability goals. This evolution not only addresses waste management challenges but also creates opportunities for companies to cater to eco-conscious consumers and enhance their market appeal.

Customization and Advanced Fabrication Techniques

The demand for customized acrylic products is driving advancements in digital fabrication technologies. These innovations allow for the rapid production of intricate designs, accommodating diverse client needs while reducing production time and costs. The flexibility offered by digital fabrication enables manufacturers to explore new creative possibilities and respond swiftly to market demands. This trend is further supported by the integration of 3D printing, which allows for the creation of unique, high-performance acrylic products tailored for specific applications across various industries, including automotive and electronics.

Market Expansion and Strategic Partnerships

Emerging markets, particularly in Southeast Asia, South America, and Africa, present significant growth opportunities for acrylic manufacturers. Companies are strategically establishing local partnerships and production facilities to penetrate these markets effectively, capitalizing on rising consumer spending power and infrastructure development. In mature markets like Europe and North America, focusing on product innovation and customization will be key for companies to enhance their competitive edge and market penetration.

Future Prospects

The future of acrylic manufacturing looks promising, driven by ongoing research and development in material technology and manufacturing processes. Continued investment in smart materials and sustainable practices will likely yield high returns as the industry adapts to evolving consumer preferences and regulatory standards. The combination of technological advancement, market expansion, and a commitment to sustainability positions the acrylic manufacturing sector for sustained growth and innovation in the coming years.

Case Studies

SCGC’s Bang Sue Model

The Bang Sue Model, initiated by SCGC in 2018, represents a significant advancement in waste management practices within the organization. This initiative focuses on optimizing resource usage and encouraging waste segregation at the source, ultimately empowering employees to recycle and reuse materials effectively. The model has inspired various community-based projects, such as the Waste-free Community and Upcycling Milk Pouches, showcasing its broader impact beyond the organization itself.

Closed-Loop Circular Appliances Initiative

In collaboration with HomePro, SCGC launched Thailand’s first “Closed-Loop Circular Appliances” initiative, which emphasizes the recycling of electrical appliances. This partnership aims to protect the environment by minimizing waste and promoting circularity in appliance manufacturing and disposal. Such collaborations are crucial in driving the transition toward more sustainable manufacturing processes in the acrylic product market.

Innovations in Acrylic Manufacturing

Recent trends in acrylic manufacturing highlight a shift toward sustainability, particularly through the adoption of bio-based PMMA and energy-efficient processes. For instance, manufacturers are increasingly leveraging renewable energy sources like solar and wind power to minimize their environmental footprint, a practice that underscores the industry’s commitment to sustainable development.

Custom Acrylic Printing Applications

Custom acrylic printing has emerged as a versatile solution for various projects, utilizing advanced UV printing technology to create vibrant and durable products. The applications of custom acrylic prints span multiple industries, demonstrating their flexibility in meeting diverse customer needs. This innovation not only enhances aesthetic appeal but also ensures longevity and resilience, making acrylic a preferred material for both indoor and outdoor use.

Market Trends and Competitor Strategies

A comprehensive analysis of the global acrylic product market reveals that companies are increasingly focusing on competitor analysis to refine their strategies and increase market share. This includes exploring new avenues for growth through mergers and acquisitions, thereby enhancing business expansion opportunities. The emphasis on customization and sustainable practices further positions acrylic products favorably in a competitive landscape, catering to the evolving demands of consumers.