Acrylic materials, also known as polymethyl methacrylate (PMMA), have become a pivotal element in rapid prototyping due to their unique combination of optical clarity, durability, and versatility. Developed in the mid-20th century, acrylic quickly gained popularity in various industries for its lightweight nature and superior resistance to environmental factors compared to traditional materials like glass and metal. Its ability to be easily machined, laser cut, and formed into intricate designs has made acrylic an ideal choice for creating prototypes that require both precision and aesthetic appeal.

Table of Contents

The significance of acrylic in prototyping is further enhanced by advancements in manufacturing technologies, such as CNC machining and laser cutting, which enable designers and engineers to produce high-quality prototypes efficiently. Acrylic’s affordability and ease of fabrication have contributed to its widespread adoption in consumer products, medical applications, and architectural designs, making it a staple material across multiple sectors. Furthermore, its biocompatibility and durability position acrylic as a critical material in the development of medical devices, underscoring its relevance in contemporary manufacturing practices.

Despite its advantages, the use of acrylic for prototyping does present challenges, such as susceptibility to scratching and limitations in high-temperature applications. Additionally, environmental concerns surrounding the production and disposal of acrylic have led to calls for more sustainable practices within the industry. As the demand for innovative design solutions grows, the future of acrylic prototyping will likely focus on enhancing its functional capabilities, exploring new applications, and adopting eco-friendly production methods to address these challenges.

History of Prototyping with Acrylic

Acrylic, a synthetic polymer also known for its optical clarity and versatility, has played a significant role in the evolution of rapid prototyping since its inception. Developed through a process called polymerization, acrylic has been widely adopted due to its lightweight, durable, and transparent properties, making it an ideal material for creating prototypes that require precision and aesthetic appeal.

The early use of acrylic in prototyping can be traced back to its commercialization in the mid-20th century, when it became accessible for various industrial applications.

Manufacturers quickly recognized its advantages over traditional materials, such as glass and metal, particularly its resistance to yellowing, cracking, and fading. This made acrylic a favored choice for creating transparent parts and models that could withstand environmental conditions, allowing for accurate representation in prototypes.

As the manufacturing landscape evolved, the introduction of advanced machining techniques further enhanced acrylic’s applicability in rapid prototyping. Techniques such as laser cutting and CNC machining allowed for intricate designs and shapes to be achieved efficiently. The affordability and sustainability of acrylic also contributed to its widespread adoption across various industries, including consumer products, electronics, and even medical applications.

Today, acrylic remains a cornerstone in prototyping, continually utilized for its versatility and ability to mimic other materials. The ongoing development in acrylic fabrication processes ensures its relevance in modern manufacturing, allowing designers and engineers to bring their ideas to life swiftly and effectively.

Properties of Acrylic Materials

Acrylic, also known as polymethyl methacrylate (PMMA), is a synthetic polymer widely recognized for its exceptional properties that make it suitable for various applications.

Physical Properties

Acrylic possesses a density of approximately 1.15-1.19 g/cm³, which is significantly lower than that of glass (2.40-2.80 g/cm³) and aluminum. This lightweight characteristic contributes to its versatility in applications ranging from household items to industrial uses. The refractive index of acrylic is about 1.49, allowing it to transmit light with an impressive clarity, rivaling that of glass by allowing 92% of white light to pass through with minimal distortion.

Mechanical Strength

One of the standout features of acrylic is its high mechanical strength. As a long-chain polymer, acrylic’s molecular structure provides it with a tensile strength that is 7 to 18 times higher than that of regular glass. Additionally, when subjected to heat and stretch treatments, acrylic’s toughness increases substantially, making it resistant to cracking even under significant stress, such as being penetrated by a nail. This treatment enables its use in safety applications like bullet-proof glass and military aircraft canopies.

Impact Resistance

Acrylic demonstrates excellent impact resistance, making it a preferred material in environments where durability is essential. It can withstand both shock and impact without shattering, which, combined with its lighter weight compared to glass, makes it ideal for protective applications.

Chemical and Temperature Resistance

Another advantage of acrylic is its resistance to various chemicals and temperature changes. It does not warp or break under temperature fluctuations, making it suitable for medical and food testing equipment that must endure extreme conditions. However, while acrylic has many benefits, it is important to note that it burns slowly and releases carbon monoxide when ignited, which is a safety consideration com- pared to other materials like polycarbonate, which self-extinguishes.

Fabrication and Workability

Acrylic is also valued for its ease of fabrication. It can be cut, drilled, sanded, and polished with standard tools without compromising its structural integrity. This work- ability, combined with its cost-effectiveness, makes acrylic an attractive alternative to more expensive materials such as metals.

Techniques for Prototyping with Acrylic

CNC Machining

Benefits of CNC Machining for Acrylic

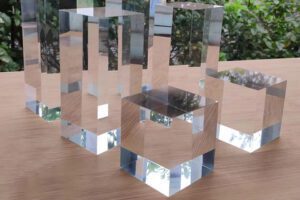

CNC (Computer Numerical Control) machining is a preferred method for prototyping acrylic parts due to its precision and efficiency. This automated process minimizes material waste by employing precise cutting paths, allowing for a clean finish and faster production cycles compared to traditional methods. CNC machining is particularly advantageous when working with cast acrylic, as it machines cleanly and produces a smooth surface that typically requires minimal post-processing.

Machining Process

The CNC machining process for acrylic involves several critical steps: Design and CAD Modeling: The initial design is created using CAD software, which serves as the blueprint for machining. Material Selection: Choosing between cast and extruded acrylic is essential, as each type has unique properties that influence the final product. Preparation: This includes setting up the CNC machine, calibrating it, and ensuring proper tool selection to prevent damage during cutting. Securing the Material: The acrylic must be securely clamped to maintain accuracy during machining.

Overview of Acrylic Prototyping

Acrylic, known for its optical clarity and weather resistance, is an ideal material for rapid prototyping in various industries. Its ability to be machined, laser cut, and formed into intricate designs makes it a versatile choice for developing prototypes that require transparency and durability.

Laser Cutting and Engraving

Laser Cutting

CNC laser cutting is a popular technique for acrylic due to its ability to create intricate cuts and engravings with high precision. The focused laser beam melts or vaporizes the acrylic, resulting in sharp edges that often do not require additional finishing. This method is particularly useful for creating components in signage and decorative items where aesthetics are paramount.

Laser Engraving

CNC laser engraving is another effective technique for modifying the surface of acrylic materials without cutting through them. This method allows for the etching of detailed designs, text, or images, enhancing the aesthetic appeal of the final product.

Additional Techniques

Flame Polishing

Flame polishing is commonly used to achieve a smooth, polished edge on acrylic parts after machining. This quick heat treatment method enhances the clarity of the acrylic edges, making it suitable for applications where optical quality is essential.

Bonding Techniques

Acrylic can also be bonded using specialized adhesives, allowing for the creation of complex assemblies that may not be achievable through traditional machining alone. This capability expands the design possibilities for prototypes.

Applications of Acrylic Prototypes

Acrylic prototypes are increasingly utilized across various industries due to their unique properties, which include clarity, durability, and versatility. As a synthetic polymer, acrylic, also known as polymethyl methacrylate (PMMA), is often preferred for its glass-like appearance and impact resistance, making it suitable for both functional and decorative applications.

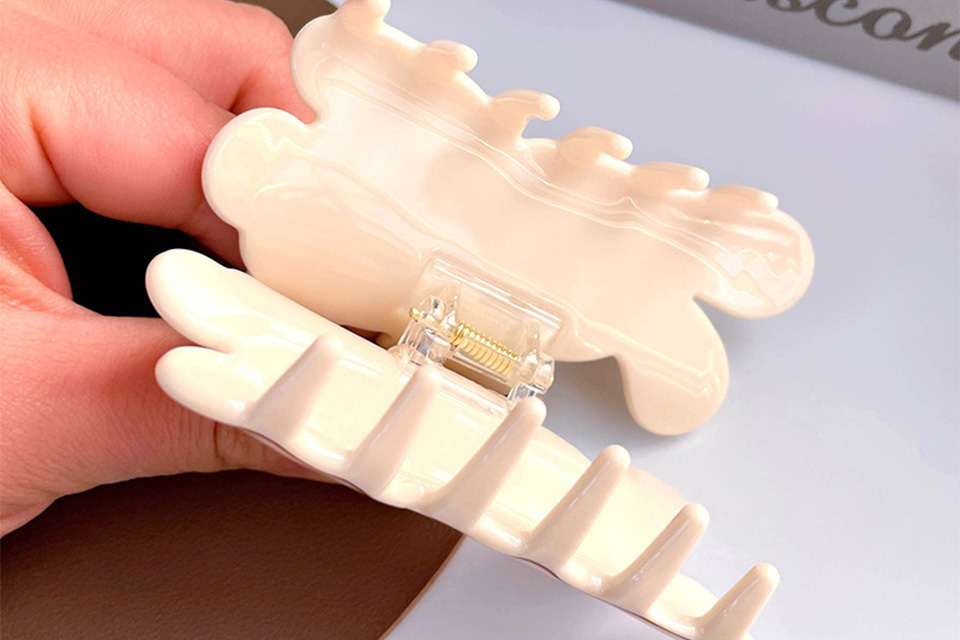

Consumer Products

Acrylic is also widely used in consumer products, including electronics, furniture, and musical instruments. Notably, items like CDs and DVDs are manufactured using acrylic materials due to their optical clarity and robustness. The material’s ability to mimic the appearance of glass while being lighter and more shatter-resistant contributes to its popularity in everyday items.

Medical Applications

One of the significant applications of acrylic prototypes is in the medical field, where its excellent biocompatibility makes it ideal for various uses. Acrylic can serve as a subcutaneous filler in cosmetic surgery and as bone cement in orthopedic procedures. These applications leverage acrylic’s ability to integrate with human tissue safely, ensuring patient comfort and efficacy in medical treatments.

Prototyping and Product Development

Acrylic materials are extensively used for rapid prototyping, which is essential for product development. Its affordability and ease of machining through CNC processes allow for quick turnaround times, making it a popular choice among designers and manufacturers. This adaptability enables creators to produce clear, durable prototypes that can accurately represent the final product, facilitating better decision-making during the design phase.

Architectural and Industrial Uses

In architecture, acrylic prototypes are employed for applications such as windshields on vehicles and skylights in buildings, showcasing its capability to withstand environmental factors while maintaining aesthetic appeal. The versatility of acrylic allows it to be molded into various shapes and sizes, further broadening its use in diverse industrial applications.

Advantages of Using Acrylic for Prototyping

Acrylic, a versatile synthetic polymer, offers numerous benefits for rapid prototyping across various industries. Its unique properties make it an ideal choice for creating prototypes that require optical clarity, durability, and cost-effectiveness.

Cost-Effectiveness

Acrylic is an affordable material, making it an appealing option for rapid prototyping. Its lower cost compared to alternatives allows businesses to produce prototypes without significant financial investment, thereby enhancing overall project feasibility. The ability to machine, laser cut, or thermoform acrylic also contributes to its cost-effectiveness, as these methods are generally less expensive and quicker than traditional prototyping techniques.

Optical Clarity and Aesthetic Appeal

One of the primary advantages of acrylic is its exceptional optical clarity. This makes it an excellent material for prototyping transparent parts and models, allowing designers to visualize their concepts effectively. Furthermore, acrylic can mimic the appearance of glass or metal, providing an aesthetically pleasing finish to prototypes without the associated weight or fragility.

Durability and Weather Resistance

Acrylic exhibits superior durability compared to other materials, as it is resistant to yellowing, cracking, and fading over time. This long-lasting quality ensures that prototypes maintain their integrity during the testing phases and beyond. Addition- ally, acrylic’s weather resistance makes it suitable for outdoor applications, ensuring prototypes can withstand various environmental conditions without degradation.

Biocompatibility for Medical Applications

Another notable advantage of acrylic is its excellent biocompatibility, making it suit- able for various medical applications. It can be utilized as a subcutaneous filler in cosmetic surgery and as bone cement in orthopedic procedures, showcasing its versatility beyond conventional prototyping uses. This property expands the scope of acrylic in industries where material safety is paramount.

Ease of Machining and Processing

The ease with which acrylic can be machined or processed is a significant advantage for prototyping. This material can be shaped and formed using various techniques, allowing for quick adjustments and iterations during the design process. Rapid proto- typing using acrylic enables designers and engineers to respond swiftly to feedback and integrate changes effectively.

Challenges and Limitations

Despite its widespread use in prototyping, acrylic materials present several challenges and limitations that designers and engineers must consider.

Material Properties

Acrylic is known for its clarity and impact resistance; however, it is not without drawbacks. One significant limitation is its susceptibility to scratching, which can compromise the aesthetic quality of the final product. While scratches can often be repaired through buffing or specialty paints, this maintenance can be a downside for applications where optical clarity is paramount, such as lenses or displays. Furthermore, acrylic is not particularly heat-resistant, which limits its use in high-temperature environments or applications requiring significant thermal stability.

Environmental Considerations

From a sustainability perspective, acrylic is a synthetic material that poses environ- mental concerns due to its non-biodegradable nature. Although it can be recycled, the overall ecological footprint of acrylic production remains a critical consideration in design projects focusing on sustainability. Manufacturers are actively researching methods to improve the sustainability of acrylic through energy-efficient production processes, but challenges remain in balancing performance with environmental impact.

Design Limitations

In the context of design processes, the traditional approach often relegates material considerations to the end stages of development. This can lead to a disconnect between the designers and the material scientists, particularly in collaborative environments focused on innovative materials development. Designers may envision applications for acrylic that exceed the material’s actual capabilities, highlighting the importance of early-stage material exploration and communication between disciplines.

Usability and Interaction Constraints

When using digital tools to simulate acrylic properties, designers and material scientists have raised concerns about potential misalignments in expectations. Tools that are not comprehensive in representing material limitations can lead to mis- understandings about what is feasible in practice. Additionally, the reliance on screens can limit the exploration of complex interaction scenarios, thus constraining the design process and potentially stifling innovation.

Future Trends in Acrylic Prototyping

The future of acrylic prototyping is expected to be shaped by advancements in technology, sustainability practices, and new applications across various industries.

Advancements in Technology

The integration of advanced manufacturing technologies such as 3D printing is revolutionizing the way acrylic prototypes are created. Techniques like Stereolithography (SLA) and Selective Laser Sintering (SLS) enable the production of complex geometries with high precision and speed, allowing for rapid iteration and refinement of designs. As these technologies become more accessible and cost-effective, the use of acrylic for rapid prototyping is likely to increase, enabling more industries to utilize its benefits.

Sustainability Practices

With growing concerns about environmental impact, the acrylic industry is exploring sustainable practices to reduce its carbon footprint. Innovations in the recycling of acrylic materials and the development of bio-based acrylic resins are gaining traction, making acrylic a more eco-friendly choice for prototyping. Additionally, manufacturers are focusing on energy-efficient production processes that minimize waste and emissions, which could enhance the appeal of acrylic in sustainability-conscious markets.

Diverse Applications

As industries continue to seek versatile materials for prototyping, acrylic is anticipated to find new applications beyond traditional uses. Its optical clarity, durability, and ability to mimic other materials like glass and metal make it ideal for creating prototypes in sectors such as automotive, consumer electronics, and medical devices. The demand for custom retail displays and signage, which often rely on acrylic for its aesthetic qualities, is also expected to rise, further driving the need for acrylic prototyping.

Enhanced Functionalities

Emerging techniques in acrylic fabrication are also set to expand the functional capabilities of acrylic prototypes. For instance, incorporating smart materials or integrating electronics into acrylic designs could lead to interactive prototypes that respond to environmental stimuli, opening up new possibilities in design and functionality. This shift could significantly enhance the prototyping process, allowing designers to create more innovative and user-centered products.

Case Studies

Overview of Acrylic Prototyping Applications

Acrylic materials are increasingly utilized in various industries for rapid prototyping due to their affordability, durability, and versatility. Companies are leveraging acrylic to develop innovative prototypes that help streamline product development processes and bring ideas to life quickly. The clear, lightweight nature of acrylic allows for effective visual presentations and functional testing, making it a preferred choice for numerous applications.

Successful Implementations

Medical Applications

Acrylic’s biocompatibility makes it an excellent material for medical prototypes. For instance, acrylic is often used in cosmetic surgery as a subcutaneous filler and in orthopedic surgery as bone cement, highlighting its significance in creating functional medical devices that require precision and reliability. Case studies demonstrate how companies have effectively utilized acrylic in developing these vital products, contributing to improved patient outcomes and surgical procedures.

Consumer Products

In the realm of consumer products, acrylic is widely employed in the creation of various items such as electronics, furniture, and musical instruments. A prominent case study showcases how an electronics company used acrylic to prototype a new line of clear sound amplification devices. By utilizing rapid prototyping techniques, the company was able to test design variations quickly and efficiently, leading to a successful product launch. This success exemplifies the critical role of acrylic in enhancing product aesthetics and functionality while maintaining cost-effectiveness.

Custom Manufacturing Solutions

Custom manufacturers have also embraced acrylic prototyping, employing CNC machining and other fabrication techniques to create tailored solutions for clients. For instance, Tri-State Fabricators, Inc. successfully crafted a series of acrylic enclosures and displays for a retail client, showcasing the material’s adaptability in commercial settings. Their ability to utilize CNC machining for precision cuts and shapes resulted in high-quality prototypes that met stringent design specifications. This case illustrates the growing trend of using acrylic for customized applications across various sectors.

Challenges and Solutions

Despite its advantages, acrylic prototyping is not without challenges. Designers often face difficulties in communicating dynamic interaction ideas effectively with materials scientists. In one case study, teams found that their initial sketches failed to convey the intended interactions clearly, leading to misunderstandings during the prototyping phase. By adopting more interactive sample books and focusing on tactile communication methods, these teams improved collaboration and ultimately produced more successful prototypes.