Summary

Custom acrylic boxes are versatile storage and display solutions made from acrylic, a synthetic polymer known for its clarity and durability. These boxes come in various shapes and sizes, allowing for extensive customization to meet diverse consumer needs across industries such as retail, events, and museums. Their ability to combine functionality with aesthetic appeal makes them a popular choice for both personal and commercial applications, enhancing the visibility and protection of items displayed or stored within them.

Table of Contents

The increasing demand for custom acrylic boxes is driven by their benefits, including lightweight durability, easy maintenance, and visual enhancement of products. Retailers use these boxes to create engaging displays that attract customers, while event planners favor them for their elegant yet practical design. Additionally, museums employ acrylic boxes to protect valuable artifacts while allowing for optimal viewing, thus improving the visitor experience.

Despite their advantages, the acrylic industry faces significant scrutiny regarding environmental sustainability. Acrylic is derived from petrochemical sources, raising concerns about its ecological footprint. Manufacturers are increasingly focused on adopting sustainable practices, such as reducing volatile organic compound (VOC) emissions and developing recyclable acrylic materials. However, challenges remain, including the complexity of recycling processes and the need for consumer aware- ness regarding the environmental impact of acrylic products.

Overall, custom acrylic boxes exemplify a balance between aesthetic appeal and functional utility, making them a favored choice across multiple sectors. Their adapt- ability, combined with ongoing innovations aimed at addressing sustainability concerns, positions them as a notable element in the design and display landscape.

Types of Custom Acrylic Boxes

Custom acrylic boxes are available in a variety of types and configurations, designed to meet diverse needs across different applications. These boxes are not only functional but also enhance the aesthetic appeal of displayed items.

Specialty Boxes

Acrylic boxes can also be customized into unique shapes and sizes tailored to specific needs. Whether for a small trinket or a large exhibit, the flexibility of acrylic allows for precise customization that caters to niche markets and commercial enterprises. Additionally, these boxes can be tinted in various colors, providing options that align with brand identities or personal preferences, enhancing their visual impact.

5-Sided Acrylic Boxes

5-sided acrylic boxes are commonly used for displaying items such as jewelry, collectibles, and art. These boxes feature an open side, making them suitable for bins, pedestals, and cover applications. Their transparent design allows for maximum visibility of the contents, appealing to both retailers and collectors.

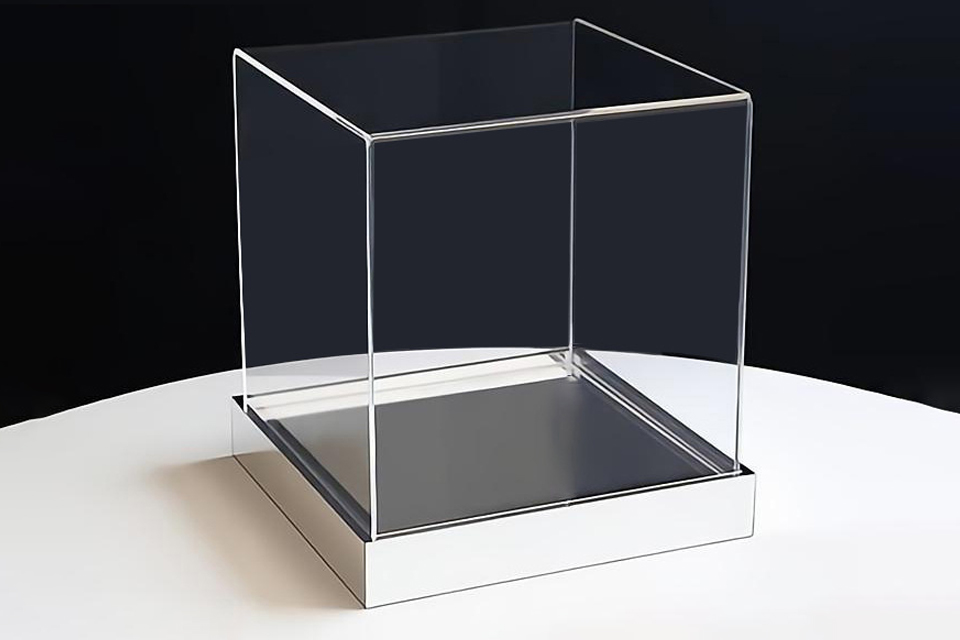

6-Sided Acrylic Boxes

In contrast to their 5-sided counterparts, 6-sided acrylic boxes come with a base and are ideal for showcasing valuable items such as jewelry or artwork in a secure manner. These boxes are often used in settings like museums or galleries, where protection and visibility are paramount.

Covered Boxes

Covered acrylic boxes, similar to traditional boxes, are designed for storage purposes. They come equipped with lids and often feature locks and handles, merging style with functionality. These boxes are perfect for safely storing a variety of items while maintaining an elegant appearance.

Square Display Cases

Square display cases are versatile and frequently used to showcase jewelry, antiques, and collectibles. Their design typically features transparent walls of uniform thickness, allowing viewers to see all sides of the displayed items, which is especially beneficial in retail or museum environments.

Additional Features

Beyond basic designs, custom acrylic boxes can incorporate branding and logo integration, making them valuable for retail displays and merchandising. Their lightweight nature also facilitates ease of transport, making them ideal for events and trade shows. Overall, the variety of types and customization options available for acrylic boxes make them a popular choice for both personal and commercial applications.

Materials and Manufacturing

Overview of Acrylic Material

Acrylic, a synthetic polymer, is a versatile material widely used in the manufacturing of custom boxes. Known for its glass-like qualities, acrylic offers exceptional optical clarity and brilliance, making it an aesthetically pleasing choice for various applications. Its lightweight and durable nature, along with high impact resistance, make it an ideal alternative to glass, especially for products that require protection and visibility. The manufacturing of acrylic typically involves two primary methods: extrusion and casting, each with distinct characteristics affecting the final product’s quality and usability.

Manufacturing Processes

Extrusion

The extrusion process involves heating acrylic into a superheated liquid, which is then forced through a nozzle to create sheets. While this method allows for continuous production, it often results in heterogeneous material properties, leading to variations depending on the extrusion direction. Extruded acrylic is generally less costly but may not offer the same level of clarity or durability as cast acrylic.

Casting

In contrast, casting involves pouring heated acrylic into molds, allowing it to cool and solidify into uniform shapes. This labor-intensive process produces more homogeneous products that are generally stronger and less prone to bending, chipping, or melting during fabrication. Cast acrylic is particularly well-suited for laser cutting, making it a preferred choice for intricate designs and high-precision applications.

Production Cycle Influences

Several factors influence the production cycle of custom acrylic boxes. A key consideration is the order quantity; larger orders typically require more time due to the need for extensive raw material procurement, equipment setup, and labor arrangements. Additionally, the complexity of the design can significantly extend production times. Processes that involve intricate cutting, molding, and assembly require careful management to ensure quality and efficiency.

Quality Control and Finishing Techniques

Ensuring the quality of acrylic materials is crucial for maintaining consistency in pro- duction. Advanced manufacturing techniques contribute to the stability and reliability of the final products. Various finishing options, such as screen printing for textured effects or UV printing for vibrant color displays, can enhance the appearance of acrylic boxes while also providing valuable product information and branding.

Sustainability Considerations

Despite its advantages, the sourcing of acrylic materials raises sustainability concerns due to its petrochemical origins. The extraction processes for these materials can have significant environmental impacts. Manufacturers are increasingly focused on addressing these issues by considering eco-friendly practices and exploring sustainable alternatives in the production of acrylic products. By understanding the materials and manufacturing processes involved, consumers and businesses can appreciate the unique qualities and benefits of custom acrylic boxes for various applications.

Applications

Custom acrylic boxes have gained significant traction across various industries due to their versatility and aesthetic appeal. These displays serve numerous purposes, enhancing both functionality and presentation in multiple contexts.

Retail Displays

Acrylic boxes are commonly used in retail settings to showcase products effectively. Their transparent nature allows customers to view items clearly while protecting them from damage. Retailers utilize custom acrylic boxes to create engaging displays that attract attention and highlight key merchandise, such as electronics, jewelry, and clothing. For example, a high-end electronics retailer faced the challenge of designing a secure yet interactive display for a new smartphone model, ultimately leading to an innovative acrylic display solution that encouraged customer interaction without compromising security.

Trade Shows and Events

In the realm of trade shows, acrylic boxes play a pivotal role in engaging potential customers. Companies often use these displays to create inviting booths that not only showcase their products but also provide essential business information through clear sign holders and promotional materials. The lightweight and portable nature of acrylic boxes makes them ideal for easy transport and setup at various events.

Special Events and Weddings

Acrylic display stands have become popular choices for special events, including weddings. They add a touch of elegance while serving practical purposes, such as: displaying table numbers, seating charts, and photos. These stands can be easily customized with names and dates to match the event’s theme, providing a sophisticated look that enhances the overall décor. Their durability and reusability make them a cost-effective solution for event planners looking to create memorable experiences.

Museum Exhibitions

Museums frequently utilize custom acrylic boxes for displaying artifacts and memorabilia. These cases not only protect valuable items from dust and handling but also enhance visibility, allowing visitors to appreciate the details of each exhibit. The adaptability of acrylic materials enables museums to design custom displays tailored to specific exhibits, improving the overall visitor experience.

Commercial and Office Applications

In office environments, acrylic boxes are employed for various organizational tasks. They are ideal for holding brochures, flyers, and other informational materials, helping to maintain a tidy workspace while ensuring that critical information is readily available. Custom acrylic solutions can also be used for office décor, integrating seamlessly into the overall aesthetic of the space.

Advantages of Acrylic Boxes

Acrylic boxes offer a multitude of advantages, making them a popular choice for various applications, from storage solutions to display cases.

Aesthetic Appeal

The clear, high-definition quality of acrylic enhances the visual presentation of items within the boxes. With their sleek and modern appearance, acrylic boxes not only serve functional purposes but also enhance the aesthetic appeal of any space. This feature is particularly beneficial in retail settings, where they can elevate the perceived value of products through polished and professional displays.

Lightweight and Durable

One of the primary benefits of acrylic boxes is their lightweight nature, which makes them easy to transport and handle. Despite being light, acrylic is exceptionally strong and resistant to impact, providing better durability compared to glass or traditional plastic options. This strength allows acrylic boxes to protect delicate items, such as jewelry and cosmetics, from damage during storage and shipping.

Versatility in Design

Acrylic boxes are highly customizable, available in a range of shapes, sizes, and thicknesses. This versatility extends to creative designs, enabling users to think outside conventional storage solutions. Whether used for personal organization or retail display, acrylic boxes can be tailored to meet specific needs, including personalized engravings and unique compartmentalization for different items.

Easy Maintenance

Acrylic boxes are easy to clean and maintain, requiring only a soft cloth and mild soap to restore their clarity and shine. This ease of care ensures that the boxes remain visually appealing over time, making them a practical choice for long-term use. Environmental Considerations Acrylic is also a sustainable option, as many acrylic products can be made from recycled materials and designed for recyclability. The longevity and durability of acrylic reduce the need for frequent replacements, conserving resources and minimizing environmental impact.

Protection from Elements

Another significant advantage is acrylic’s resistance to UV light and weathering, which ensures that it does not yellow or degrade over time. This characteristic makes acrylic boxes suitable for both indoor and outdoor applications, providing reliable protection for stored items.

Environmental Impact

Sustainability in Acrylic Production

Environmental sustainability is increasingly becoming a cornerstone of the acrylic industry, with a notable shift towards developing eco-friendly and recyclable acrylic materials. This transition aims to reduce the environmental impact associated with both the production and disposal of acrylic products. Manufacturers are actively working to lower volatile organic compound (VOC) emissions, which aligns with global environmental regulations and responds to the rising consumer demand for environmentally responsible options.

Challenges and Opportunities

While the move towards sustainable practices presents opportunities for innovation and growth, it is not without its challenges. The high costs associated with developing and implementing sustainable technologies can pose significant barriers, especially for smaller manufacturers. Additionally, the recycling process for acrylic remains complex and costly, necessitating substantial investments in infrastructure and in- novation. Consumer awareness also plays a crucial role; many buyers remain unaware of the environmental implications of their material choices, despite a growing interest in sustainable products.

However, these challenges create pathways for advancements. Governments and organizations worldwide are incentivizing sustainable manufacturing practices, prompting companies to invest in greener technologies. Collaborations among manufacturers, researchers, and policymakers can accelerate the development of eco-friendly acrylic solutions. Educating consumers about the benefits of sustainable acrylic products can further stimulate demand, fostering a positive cycle of innovation and adoption.

Circular Economy and Recycling

The concept of a circular economy, which emphasizes the reuse and recycling of materials to minimize waste, has become a guiding principle for the acrylic industry. Manufacturers are collaborating with designers and end-users to create products that are easier to recycle or repurpose at the end of their lifecycle. Initiatives such as take-back programs, where used acrylic products are returned to the manufacturer for recycling, help reduce landfill waste and promote a sense of responsibility among consumers and businesses. Although recycling acrylic poses challenges due to its chemical stability, advancements in technology are making it increasingly feasible to break down used acrylic into its core components for reuse. Closed-loop recycling systems are gaining traction, allowing acrylic waste to be collected, processed, and reintroduced into the production cycle. This approach conserves natural resources and minimizes the demand for virgin materials.

Energy Efficiency in Production

Energy efficiency is another vital focus area within the acrylic industry. Modern manufacturing facilities are increasingly powered by renewable energy sources, such as solar and wind power. By optimizing production processes and investing in energy-efficient equipment, manufacturers can significantly reduce their greenhouse gas emissions. Some companies are also exploring advanced technologies like car- bon capture and storage (CCS) to mitigate their environmental impact further.