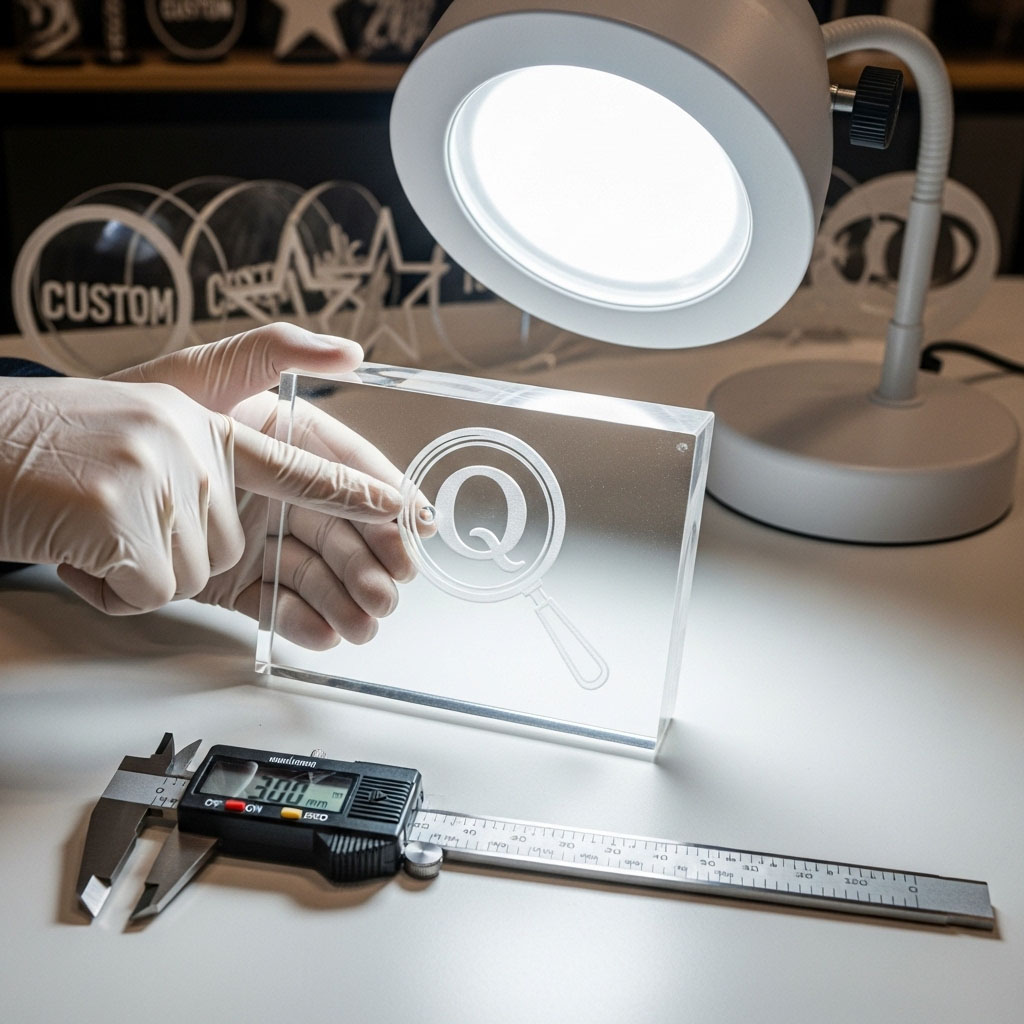

Quality Control in Custom Acrylic Manufacturing

At our factory, quality is never an afterthought—it’s our foundation. Every piece of acrylic that leaves our facility is rigorously inspected and tested to meet the highest standards of durability, clarity, finish, and precision. Whether you're ordering custom acrylic displays or acrylic furniture, our quality control process ensures your product arrives flawless and production-ready.

Our Commitment to Quality

We understand that our clients: retailers, designers, event planners, and corporate buyers who depend on us for products that reflect their brand integrity. That’s why we combine advanced production equipment with human expertise to inspect every item at multiple stages.

What We Guarantee:

Crystal-clear optical finish

Precision cuts and measurements

Bonding strength and durability

No bubbles, cracks, or surface flaws

Accurate color and engraving reproduction

Scratch and defect-free surfaces

Quality Control Process by Product Category

Custom Acrylic Displays

We check for visual consistency, uniform dimensions, sturdy bonding, and stable freestanding designs. Whether it's for cosmetics or retail, each display stand must meet load-bearing and transparency requirements.

QC Focus:

1. Load testing for product weight

2. Edge polish and bonding strength

3. Structural symmetry and stability

Custom Acrylic Boxes

Every box is measured for fit, clarity, and joint integrity. Lids must open smoothly, and engravings or printed logos are inspected for alignment and durability.

QC Focus:

1. Lid fit and hinge function

2. Logo placement and print resistance

3. Bubble-free joints and sealing

Custom Acrylic Crafts

These creative products require precision, especially for irregular shapes, embedded items, or mixed-material compositions. We scrutinize each detail to ensure artistic value and technical perfection.

QC Focus:

1. Sharp detail and clean laser edges

2. Uniform finishes for artistic consistency

3. No visual distortions or inclusions

Custom Acrylic Trophies & Awards

Each award is a symbol of excellence—it must be flawless. We examine engraving clarity, geometric balance, and base adhesion to ensure a premium look and feel.

QC Focus:

1. Clarity of text and logos

2. Smoothness of contours and shapes

3. Secure base attachment

Custom Acrylic Signs

Your signage reflects your brand—we verify every cut, font alignment, backlighting integration, and color match before shipment.

QC Focus:

1. Color calibration and consistency

2. Font sharpness and correct sizing

3. Adhesive strength of vinyl or UV print

Custom Acrylic Trays

Trays must be smooth, stable, and safe. We inspect load-bearing capacity, clarity, and handle strength (if applicable).

QC Focus:

1. Smooth base and edge polishing

2. Handle adhesion (if attached)

3. Food-grade compatibility checks (when applicable)

Custom Acrylic Furniture

These products are checked for inner and outer diameter consistency, clarity, and machining readiness.

QC Focus:

1. Roundness and wall uniformity

2. Clean inner and outer surfaces

3. UV resistance (on request)

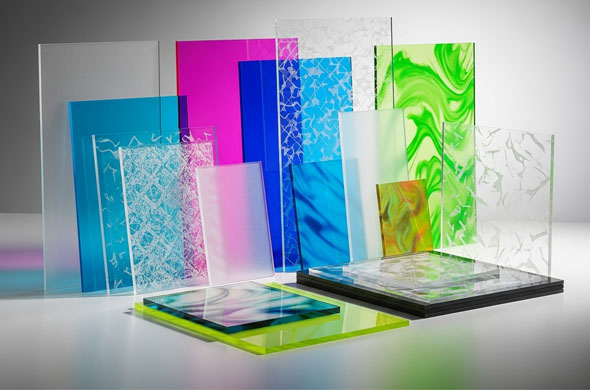

Custom Acrylic Sheets

As the raw material behind many products, sheets are inspected for thickness uniformity, optical clarity, and defect-free surfaces.

QC Focus:

1. Thickness within +/- 0.2 mm tolerance

2. No bubbles, warping, or yellowing

3. Color accuracy for tinted sheets

Custom Acrylic Rods & Tubes

We check for visual consistency, uniform dimensions, sturdy bonding, and stable freestanding designs. Whether it's for cosmetics or retail, each display stand must meet load-bearing and transparency requirements.

QC Focus:

1. Load testing for product weight

2. Edge polish and bonding strength

3. Structural symmetry and stability

Trust in Every Detail

Your brand deserves acrylic products that don’t just look good—but last, perform, and impress. With our structured quality control system, you can trust that your custom acrylic order will arrive on time, on spec, and inspection-ready.

Final Inspection

Quality Certifications