Summary

Hanging acrylic signs are a popular choice for businesses and organizations seeking to enhance their visibility and branding in a stylish and modern manner. These signs, crafted from lightweight and durable acrylic material, are celebrated for their versatility, optical clarity, and resistance to breaking, making them suitable for both indoor and outdoor applications. Their aesthetic appeal, combined with practical functionality, has led to an increased demand for effective installation techniques that ensure both security and visual impact.

Notably, the installation of acrylic signs involves careful selection of materials, mounting hardware, and adherence to proper techniques to achieve a successful outcome. Mounting methods can vary widely, including standoff mounts that provide a modern three-dimensional look, as well as adhesive options that create a sleek, hardware-free appearance. However, the process is not without its challenges; common pitfalls such as improper surface preparation, inadequate weight support, and non-compliance with local regulations can lead to installation failures and safety hazards.

Moreover, the aesthetic considerations of hanging acrylic signs extend beyond mere functionality. Color schemes, finishes, and custom shapes play a critical role in aligning the signage with brand identity and enhancing visual appeal. As businesses continue to recognize the importance of effective signage in their marketing strategies, understanding the nuances of installation and maintenance becomes increasingly vital.

In light of these factors, proper maintenance and periodic inspections are essential to ensure the longevity and effectiveness of acrylic signs, safeguarding against wear and environmental damage. By focusing on the right materials, techniques, and safety protocols, installers can achieve a visually striking and secure display that meets both functional and aesthetic demands.

Table of Contents

Materials

When preparing to hang acrylic signs, selecting the right materials is essential for ensuring a secure and visually appealing installation. Key materials include the acrylic sign itself, mounting hardware, and tools for installation.

Acrylic Sign

Acrylic signs are made from a flexible, translucent polymer that offers several advantages over glass. They are lightweight, durable, and much less susceptible to breaking, making them particularly suitable for outdoor use. Acrylic sheets come in a variety of thicknesses, typically ranging from 1/16 inch (1.5 mm) to 4 inches (100 mm) or more, with thicker sheets providing enhanced durability. Additionally, the optical clarity of acrylic enhances the appearance of the sign, providing a clean, professional look.

Mounting Hardware

Choosing the appropriate mounting hardware is critical for the stability and safety of acrylic signs. Various options are available, including standoff mounts, wall anchors, and brackets. Standoff mounts create a modern look by providing a gap between the sign and the wall, resulting in a three-dimensional effect. When selecting hardware, ensure that it can support at least 1.5 times the weight of the sign to maintain stability.

Tools

To facilitate a successful installation, several tools are necessary. Common tools include a measuring tape or ruler, level, and drill. A level ensures that the sign is hung straight, while a drill allows for the creation of pilot holes for mounting hardware. It’s also advisable to have a measuring tape on hand to mark precise locations for mounting, ensuring the sign is placed in optimal positions for visibility and impact.

Preparation

Before beginning the installation of acrylic signs, thorough preparation is essential to ensure a successful outcome. This process begins with gathering all necessary tools and materials required for the job, which may include items such as a measuring tape, level, drill, wall anchors, and protective gloves. Having these tools ready beforehand minimizes interruptions and contributes to a smoother installation process.

Creating a Detailed Installation Plan

A comprehensive installation plan is crucial. This plan should take into account every potential variable that may arise during installation. For instance, measuring the installation space multiple times is advisable to confirm wall dimensions and identify any electrical lines or potential mounting challenges. In high-traffic areas, even slight misalignments can negatively impact the professional appearance of the sign, so precision is key.

Installation Checklist

Developing an installation checklist can facilitate the process. This checklist should include all necessary tools, hardware, and safety equipment, ensuring nothing is overlooked. Professional installers often recommend keeping a backup set of mounting hardware on hand to address any unexpected issues that might occur during installation.

By following these preparation steps, installers can set themselves up for a successful and aesthetically pleasing installation of acrylic signs.

Installation Techniques

Installing acrylic signs requires careful planning and execution to ensure both security and aesthetics. The following techniques will help achieve a successful installation.

Common Mistakes to Avoid

Proper planning is crucial for a successful installation. Common pitfalls include poor surface preparation, using the wrong mounting hardware, and ignoring local regulations regarding sign placement. Ensure that the surface is clean and free from contaminants to facilitate strong adhesion. Additionally, verify that the chosen hardware can support the weight of the sign without compromising stability.

Lastly, maintain awareness of weight distribution and weatherproofing, especially for outdoor signs, to enhance their durability and visibility over time. Establish a routine maintenance schedule to address any issues that may arise, prolonging the sign’s lifespan and effectiveness.

Preparing for Installation

Before beginning the installation, it is essential to gather all necessary tools and materials. Choose the right mounting method based on the space available, considering options like standoffs, screws, or adhesive pads. Use a measuring tape to accurately mark the mounting points, and ensure that these points are level to avoid misalignment. Double-check all measurements and mark where screws or adhesive will be placed to ensure precision.

Mounting Methods

Drilling

For installations requiring drilling, follow these steps:

Use a drill to create small holes at the marked points. If needed, insert wall anchors for added stability.

Carefully screw the acrylic sign into place, ensuring that it is securely fastened to the wall.

Adhesive

If opting for adhesive installation, apply the adhesive evenly on the back of the sign. Press it firmly against the wall or stand and hold it in place for a few seconds to ensure a strong bond. This method is particularly effective for providing a sleek look without visible hardware.

Standoffs

Standoffs are a popular choice for mounting acrylic signs, providing a three-dimensional effect. The standoff system includes components such as anchors, set screws, and barrels.

Position the signage using a level and mark the hole positions on the sign.

Drill holes based on the size of the standoffs being used and ensure they are evenly spaced.

Attach the standoff barrels to the wall using anchors and set screws, then secure the signage in place.

Maintenance and Care

Proper maintenance is essential for ensuring the longevity and effectiveness of hanging acrylic signs. Regular attention not only enhances the visual appeal of the sign but also contributes to its overall functionality and safety.

Importance of Routine Maintenance

Establishing a routine maintenance schedule is crucial to catch potential issues before they escalate. Regular inspections can identify signs of wear, such as fading, cracking, or loosening of hardware, which if neglected could lead to significant problems and costly repairs. Cleaning the sign regularly helps remove dirt, debris, and environmental pollutants that accumulate over time, maintaining the sign’s visibility and enhancing its appearance.

Cleaning Procedures

When cleaning acrylic signs, it is important to use gentle methods to avoid damaging the surface. Avoid harsh cleaning chemicals, as these can cause scratches or discoloration. Instead, opt for mild soap and water, and consider using a soft cloth or microfiber towel for wiping. For signs exposed to direct sunlight, occasional polishing can help maintain clarity and luster.

Inspecting for Damage

Periodic inspections should include checking the mounting hardware and surrounding area for any signs of instability or deterioration. It is vital to ensure that the sign remains securely fastened and adheres to local safety regulations. Attention to load-bearing limits specified by manufacturers can prevent potential hazards associated with exceeding these limits.

Professional Assistance

While DIY solutions may suffice for minor maintenance, more significant repairs and refurbishments often require professional expertise. Consulting with signage professionals can ensure that any issues are addressed properly and effectively, thereby extending the life of the sign.

Style and Aesthetics

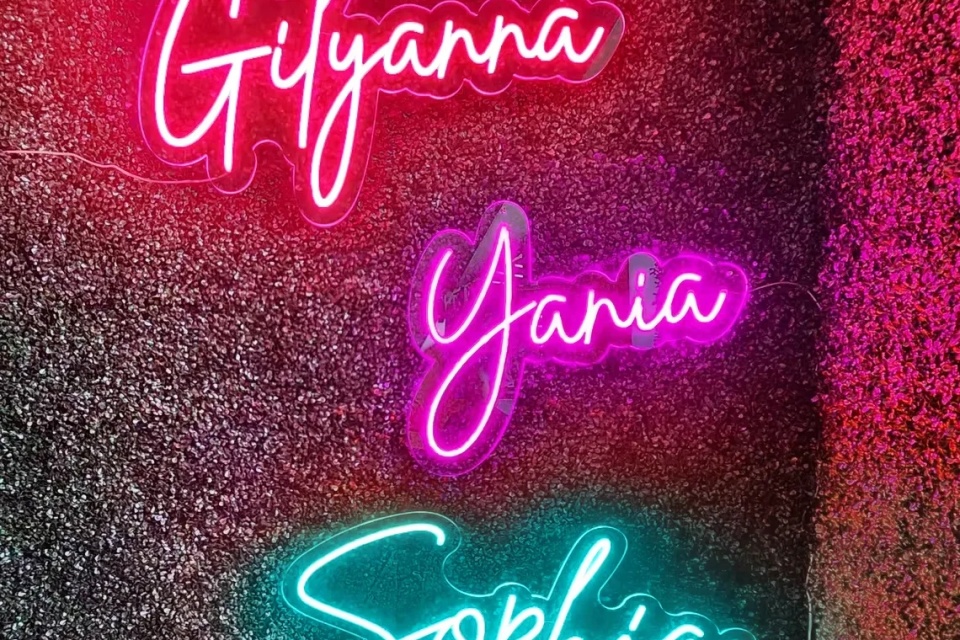

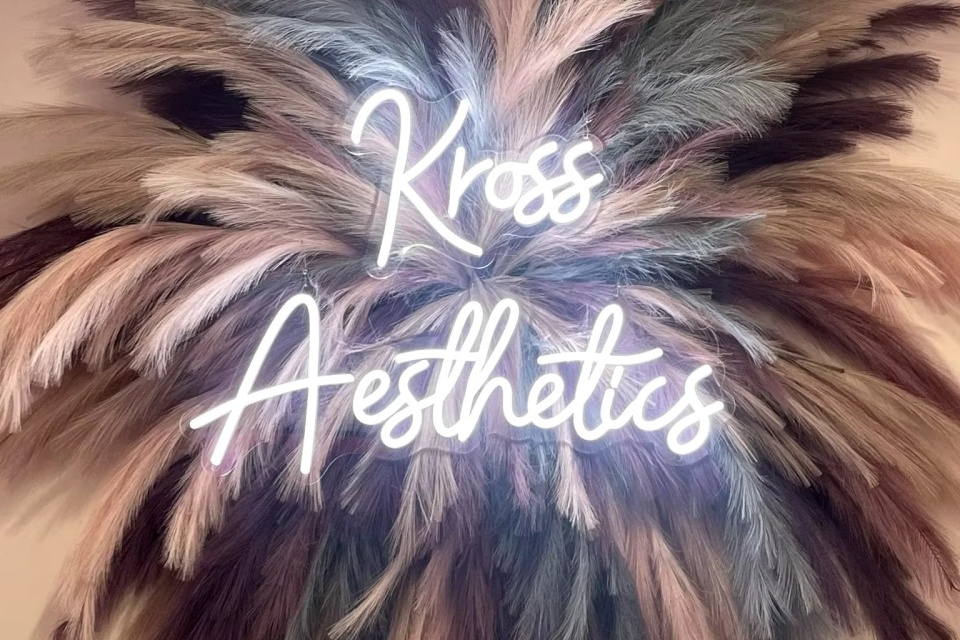

The style and aesthetics of hanging acrylic signs are pivotal in ensuring they not only serve their functional purpose but also enhance the visual appeal of their environment. Color plays a crucial role in this aspect, as it can evoke emotions and influence perceptions, thereby shaping the overall brand identity of the space. When designing acrylic signage, selecting colors that align with the intended message is essential; for instance, warm, vibrant hues may convey energy for a gym, while cool, muted tones could foster a calming atmosphere in a library.

Color Schemes and Effects

Incorporating effective color schemes can significantly elevate the aesthetic quality of acrylic signs. Triadic color schemes provide a bold contrast, creating vibrant looks that capture attention. Alternatively, monochromatic schemes, which utilize varying shades of a single color, can offer a cohesive and sophisticated appearance, though care must be taken to avoid a lack of contrast.

Additional design techniques, such as the use of light-up effects with embedded LED lights, can further enhance the appeal of acrylic signs. This approach not only adds a festive glow but can also reflect holiday themes through colored acrylic sheets. Furthermore, layering techniques involving paint and textures, such as lace overlays or laser etching, allow for personalized touches that resonate with the intended audience, making the signs more memorable.

Finishes and Materials

The finish of acrylic signs also impacts their visual appeal. Matte finishes, for example, are favored for their elegance and reduced glare, making them suitable for both indoor and outdoor use. They help maintain readability in varying lighting conditions while enhancing the overall design without overwhelming other elements. Conversely, incorporating metallic finishes can add a touch of sophistication, appealing to luxury brands and premium services.

Customization and Detail

Custom shapes that align with a business’s branding or storefront can contribute significantly to the overall aesthetics of acrylic signage. Attention to detail, such as polishing cut edges to improve light transmission, can elevate the quality of the sign and its appearance. Aspects like layering colors using shades, tints, and tones also create depth and visual interest, enhancing the overall impact of the signage.

Safety Considerations

Ensuring safety during the installation of acrylic signs is paramount. Various factors must be considered to prevent accidents and guarantee a secure setup.

Tools and Equipment

Using the right tools for the job is essential. Proper safety training should be provided to all team members involved in the installation process to minimize risks. Adhering to occupational safety standards specific to each state helps ensure the safety of personnel and those nearby the installation site. Additionally, selecting high-quality materials and tools, such as Gorilla tape, which offers significantly stronger holding power than traditional duct tape, can help reduce time and frustration in the field.

Weatherproofing and Load-Bearing Limits

Outdoor signs must be weatherproofed to withstand harsh environmental conditions, as neglecting this can lead to fading and deterioration that compromise the sign’s visibility and longevity. Moreover, installers must never exceed the load-bearing capacity of mounting hardware. Adhering to the specifications provided by manufacturers and structural engineers is crucial to prevent instability and potential collapse, which can pose serious safety hazards.

Proper Surface Preparation and Hardware Selection

Adequate surface preparation is necessary for strong adhesion and longevity. This includes cleaning the mounting surface to remove contaminants that could affect installation quality. Selecting the appropriate mounting hardware is equally critical. Installers should choose hardware capable of supporting at least 1.5 times the weight of the sign to ensure long-term stability, taking into account the specific environmental conditions the sign will face.

Risk Mitigation during Installation

Before beginning any installation, a thorough assessment of the physical space is essential to identify potential challenges, such as inadequate lighting or unsuitable mounting surfaces. Understanding client requirements and reviewing blueprints can help prevent complications. Moreover, ensuring accessibility during installation is vital to avoid accidents related to tight spaces or obstructions.

Compliance with Regulations

Installers must be familiar with and adhere to local regulations governing sign placement and size. Failure to comply with zoning laws can lead to fines and legal issues, making it crucial to research permit requirements prior to installation.

By prioritizing these safety considerations, installers can minimize risks and ensure a secure and effective installation of acrylic signs.