Summary

The right acrylic thickness is a crucial consideration in various applications, impacting the material’s performance, aesthetics, and safety. Acrylic, a versatile thermoplastic, is widely used in industries ranging from signage and display to architecture and automotive. The thickness of acrylic sheets directly influences their durability, light transmission, and overall suitability for specific tasks. Selecting the appropriate thickness ensures that projects not only meet functional requirements but also adhere to safety standards, enhancing user protection and longevity of the installation.

Table of Contents

Acrylic sheets are categorized primarily into two types—cast and extruded—each with distinct properties and ideal thickness ranges for different applications. Cast acrylic offers superior optical clarity and resistance to scratching, making it favorable for high-end uses such as aquariums and medical devices, while extruded acrylic is more economical and consistent in thickness, often employed in signage and lighting applications. Understanding the differences between these types is essential for making informed decisions about thickness based on the intended use, environmental conditions, and budgetary constraints.

Controversies surrounding acrylic thickness often center on misconceptions that thicker is always better. While increased thickness can enhance durability and impact resistance, it may not always be necessary or practical for every application. Thinner sheets can provide excellent optical clarity and are often easier to handle. Therefore, evaluating the specific demands of a project—including structural integrity, desired aesthetic outcomes, and exposure to elements—is vital to selecting the right acrylic thickness.

In addition to performance characteristics, safety regulations and industry standards play a significant role in determining acrylic thickness. Adherence to guidelines such as ANSI Z97.1 ensures that acrylic products meet necessary safety benchmarks, particularly in applications involving structural or glazing materials. By understanding the complexities of acrylic thickness, designers and manufacturers can achieve optimal results while addressing both functional and aesthetic considerations.

Types of Acrylic

Acrylic sheets are primarily categorized into two main types based on their production methods: cast acrylic and extruded acrylic. Each type possesses distinct properties and applications, making them suitable for various uses.

Cast Acrylic

Cast acrylic sheets are manufactured by pouring liquid methyl methacrylate (MMA) into molds, where the mixture undergoes a controlled polymerization process. This method results in a dense, high-quality sheet with superior optical clarity, making cast acrylic ideal for applications requiring high transparency and durability, such as aquariums, luxury retail displays, and medical devices. Cast acrylic is known for its excellent scratch and chemical resistance, which further enhances its appeal for high-end uses.

Extruded Acrylic

Extruded acrylic sheets, on the other hand, are produced by continuously pushing melted acrylic through a die. This process generates a cost-effective material with consistent thickness, making extruded acrylic suitable for large-scale production and signage applications where uniformity is critical. While extruded acrylic is generally more affordable, it is slightly softer than cast acrylic and thus more susceptible to scratches. Despite this, it remains a popular choice for applications like light lenses and instrument clusters in the automotive and aviation industries due to its lightweight properties and impact resistance.

Comparison of Cast and Extruded Acrylic

The primary difference between cast and extruded acrylic lies in their manufacturing processes and resultant characteristics. Cast acrylic offers superior optical clarity and durability, making it a preferred choice for specialty applications, while extruded acrylic is favored for its cost-effectiveness and ease of handling in large-scale projects. Understanding these differences is crucial when selecting the appropriate type of acrylic for specific needs and applications.

Factors Influencing Acrylic Thickness

Choosing the appropriate acrylic thickness is essential for ensuring the success of a project. Several factors influence this decision, each playing a crucial role in determining the most suitable thickness for specific applications.

Purpose and Application

The intended use of the acrylic sheets significantly affects the required thickness. Different applications, such as signage, display cases, protective barriers, and decorative panels, necessitate varying thicknesses to achieve optimal performance and longevity. For example, thicker sheets are often preferred for aquariums or display cases where optical clarity and impact resistance are paramount. In contrast, thinner sheets might suffice for applications that do not face significant wear or stress.

Structural Integrity and Safety

Acrylic thickness directly impacts the structural integrity and durability of applications. Insufficient thickness can lead to instability or breakage, posing safety risks to users. Therefore, adhering to recommended thicknesses is crucial for increasing protection and ensuring the longevity of the installation.

Environmental Conditions

The environment in which the acrylic will be used also plays a significant role in thickness selection. Factors such as temperature fluctuations, exposure to UV light, and potential physical impacts should be considered. Thicker acrylic sheets generally offer better resistance to weathering and impacts, making them suitable for outdoor applications or areas with high foot traffic.

Budget Considerations

Budget constraints are a critical factor in selecting acrylic thickness. Thicker sheets usually come at a higher cost due to increased material and processing requirements. While thinner sheets may reduce initial costs, they may not provide the durability needed for long-lasting applications, potentially leading to higher replacement costs over time. Therefore, it is essential to evaluate project requirements against financial limitations to strike a balance between performance and cost.

Light Transmission Properties

The desired optical properties also influence the choice of acrylic thickness. As thickness increases, light transmission can be affected, with thicker sheets typically exhibiting slightly lower transmission rates. Designers must consider how the thickness will impact light transmission in both architectural and display applications to achieve the desired aesthetic and functional outcomes. Moreover, the interaction of color with thickness further complicates this selection, as darker colored sheets may allow less light compared to lighter options.

Recommended Thickness for Various Applications

Acrylic sheets are available in a variety of thicknesses, each suited for specific applications depending on the requirements for durability, strength, and aesthetics. Below is a guide to the recommended thicknesses for various uses.

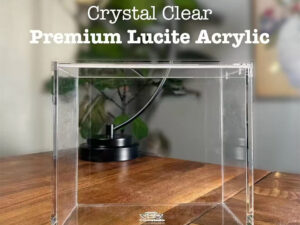

Display Cases

For display cases used in museums or at home, 1/4″ to 3/8″ acrylic sheets are recommended. These thicknesses offer excellent clarity and a sturdy look, making them perfect for showcasing items while providing adequate protection.

General Use

For everyday applications such as tabletops, larger shelves, display cases, and outdoor signage, a thickness of 1/4″ to 3/8″ (6 mm to 9.5 mm) is typically recommended. This range provides a good balance of strength and transparency, capable of supporting moderate weight effectively.

Retail Displays

When designing retail displays that need to support products, a thickness of 1/2″ to 1″ (12 mm to 25 mm) is ideal. Thicker acrylic sheets in this range not only offer superior strength but also enhance the premium appearance of the display, making them suitable for high-end retail environments.

Heavy-Duty Applications

In scenarios that require extra durability, such as protective barriers or countertops, a thickness of 1/2″ to 3/4″ (12 mm to 18 mm) is preferred. This range is designed to handle significant wear and tear, making it suitable for high-traffic areas and demanding environments.

Jewelry and Artwork Displays

For high-end jewelry or artwork displays, utilizing acrylic sheets ranging from 1″ to 4″ (25 mm to 100 mm) is advised. Thicker sheets in this category provide a luxurious, modern appearance while securely supporting valuable items, making them ideal for specialized showcases.

Specialized Applications

In specialized applications such as aquariums or security barriers, acrylic sheets of 20 mm or more can be used. These extra-thick sheets provide maximum impact resistance and are designed to withstand extreme conditions and forces.

Considerations for Thickness

While thicker acrylic sheets generally offer better durability and impact resistance, it is essential to consider factors such as the specific application, installation environment, and desired aesthetic outcomes. Regular maintenance, including cleaning and inspection for stress signs, can help ensure the longevity of the acrylic installation.

Manufacturing and Processing

Production Techniques

The manufacturing of acrylic involves various techniques that significantly impact the final product’s quality and characteristics. The two primary methods of acrylic production are extrusion and casting. Extrusion is a continuous process in which heated acrylic is forced through a mold to create sheets, while casting can be achieved through batch cell or continuous production techniques, allowing for the creation of thick and flawless acrylic sheets. To enhance product quality and consistency, manufacturers regularly calibrate production equipment, such as molds and extruders, to maintain operational accuracy. This attention to detail is crucial in high-end application scenarios where precision is essential.

Quality Assurance

Ensuring the quality of finished acrylic products involves rigorous testing. High-precision measuring equipment is utilized to sample and test various properties, such as optical characteristics (transmittance and haze) and surface smoothness. Advanced production technologies and strict online monitoring processes contribute to achieving desired quality standards while improving production efficiency and customer satisfaction.

Thickness Considerations

Thickness is a vital factor in the manufacturing process, influencing the performance and suitability of acrylic sheets for specific applications. Acrylic sheets are available in a broad range of thicknesses, typically from 1mm to 50mm or more. Thinner sheets, between 1mm and 3mm, are lightweight and flexible, making them ideal for applications requiring intricate shaping, while thicker sheets provide enhanced strength and durability for more demanding uses. When selecting the appropriate thickness, factors such as load-bearing capacity, impact resistance, and flexibility must be considered to ensure the best results for the intended project. The right thickness not only affects functionality but also plays a crucial role in the overall design and aesthetic appeal of the final product.

Quality Control Measures

Quality control in the production of acrylic sheets is crucial for ensuring optimal performance and reliability. Manufacturers implement a variety of measures to monitor and maintain the quality of their products throughout the manufacturing process.

Testing Procedures

A comprehensive quality assurance process includes extensive UV resistance testing conducted in controlled environments. Facilities simulate accelerated weathering conditions to provide data equivalent to years of natural exposure, ensuring that the acrylic sheets can withstand prolonged exposure to sunlight and other environmental factors. Additionally, finished products undergo rigorous testing using high-precision measuring equipment to verify optical properties such as transmittance and haze, as well as surface smoothness. Regular quality checks are performed on production batches to maintain consistency and adherence to high standards across all products.

Production Techniques

The selection of appropriate raw materials and production methods significantly influences product quality. Manufacturers utilize high-quality methyl methacrylate (MMA) monomer to ensure stability in the polymerization process and the addition of cross-linking agents and other additives optimizes material properties. The two main production methods—extrusion and casting—each have specific advantages that affect quality. The casting method allows for better control of thickness uniformity through the injection of liquid monomer into molds, while extrusion, although suitable for large-scale production, can result in heterogeneous properties due to variations in the direction of extrusion.

Thickness and Surface Control

Ensuring uniform thickness and surface smoothness is paramount, as these factors directly impact the optical and mechanical properties of acrylic sheets. Advanced monitoring systems, such as high-precision thickness measuring instruments, are installed to provide real-time feedback during production, allowing for automatic adjustments to keep thickness deviations within acceptable limits (typically ±0.1mm or less). Additionally, the design and accuracy of molds play a critical role in achieving consistent sheet thickness during the casting process, while the extrusion method relies on precise control of the die head to ensure stable material flow and pressure.

Post-Production Treatments

After manufacturing, acrylic sheets often undergo post-treatment processes to relieve internal stress and enhance performance. For cast acrylic, conditions such as heating at 60 °C and 120 °C for specified durations help solidify the material’s properties. Similarly, extrusion products may require additional post-treatment in a hot air circulation drying oven to eliminate any internal stresses introduced during the manufacturing process. By implementing these rigorous quality control measures, manufacturers like Jinbao Plastic aim to deliver acrylic sheets that meet high performance and safety standards, ensuring long-term reliability for various applications.

Advantages of Using the Right Thickness

Choosing the correct thickness of acrylic sheets is vital for enhancing the overall performance and aesthetics of various projects. The appropriate thickness not only influences the durability and functionality of the acrylic but also affects its visual appeal and safety in applications.

Durability and Strength

Acrylic sheets come in a range of thicknesses, and selecting a thicker sheet generally enhances its resistance to impacts and bending, making it ideal for high-traffic areas or environments where the material may encounter knocks or bumps. Thicker sheets offer better protection against harsh weather conditions, which is particularly important for outdoor installations. This resilience ensures that the material maintains its functional and visual integrity over time.

Safety Considerations

Maintaining the correct acrylic thickness is crucial for structural integrity and safety. Insufficient thickness can lead to instability or breakage, posing risks to users. Therefore, selecting an appropriate thickness is essential to ensure user safety and compliance with safety standards. Variations in thickness can result in uneven weight distribution, potentially compromising the structure’s reliability.

Aesthetic Appeal

The thickness of acrylic sheets can significantly impact their aesthetic qualities. Thicker sheets provide a more substantial appearance, contributing to a more luxurious look in design applications. Additionally, colored acrylic sheets are available in a variety of thicknesses, allowing designers to create unique and visually appealing elements that enhance the overall impact of their projects.

Versatility in Applications

Acrylic sheets with the right thickness can be molded, cut, and shaped to meet diverse design requirements. This versatility allows for innovative applications across various sectors, from architectural elements to retail displays. The flexibility to adapt the thickness for specific needs opens up creative possibilities for engineers and designers alike.

Easy Maintenance

Acrylic sheets are inherently resistant to stains and moisture, making them ideal for applications in environments such as kitchens and bathrooms. Selecting an appropriate thickness can further enhance these properties, ensuring longevity and reducing maintenance requirements. The non-porous surface of acrylic sheets prevents water damage and simplifies cleaning processes, making them a practical choice for many settings.

Common Misconceptions

Many misunderstandings surround the use of acrylic and its thickness, often leading to confusion in various applications. One prevalent misconception is that thicker acrylic is always better. While thicker sheets do offer enhanced durability and impact resistance, they can also be heavier and less flexible, which may not be suitable for all projects. In contrast, thinner acrylic sheets can provide superior optical clarity and are easier to handle, making them ideal for applications where visual appeal is paramount.

Another common belief is that acrylic is synonymous with glass. While acrylic does possess many glass-like qualities, such as transparency and brilliance, it is actually a type of hard plastic that is significantly lighter and more impact-resistant than glass. This distinction is crucial for applications where safety and durability are priorities, such as in protective barriers or sporting equipment.

Additionally, there is a misconception that all acrylic sheets are created equal. The manufacturing method can greatly affect the properties of the acrylic. For example, cast acrylic generally provides superior mechanical properties compared to extruded acrylic, making it a better choice for structural applications.

Finally, some may assume that any thickness will suffice for their specific project needs. However, the right acrylic thickness is essential for balancing aesthetics, functionality, and durability. Understanding the specific requirements of each project, including environmental exposure and load-bearing demands, is vital for achieving the desired outcome.

Safety Standards and Regulations

Acrylic sheets are subject to various safety standards and regulations to ensure their safe use in a variety of applications. One of the key standards is the ANSI Z97.1-1994, which focuses on safety glazing materials used in buildings, confirming that acrylic sheets meet necessary safety and quality benchmarks. Additionally, compliance with the Federal Motor Vehicle Standard 2-5 and ANSI Z26.1 further underscores the importance of safety in the manufacturing and application of acrylic products.

To enhance safety, acrylic sheets can also be treated with safety films that adhere to ANSI Z97.1 and/or CPSC 16CFR 1201 standards, providing an additional layer of protection for glass products used in both commercial and residential settings. Furthermore, manufacturers such as Laser Safety Industries ensure that their acrylic windows are designed to comply with ANSI Z136.1 standards, particularly when utilized in conjunction with laser systems.

Maintaining compliance with these standards not only assures users of the product’s safety but also protects them from potential hazards associated with inadequate thickness or structural integrity. It is crucial for manufacturers and users alike to be aware of these regulations when selecting acrylic thickness for various applications, as insufficiently thick sheets can compromise safety and durability, leading to potential risks for users.

The Right Acrylic Thickness

Understanding Acrylic Thickness

The thickness of acrylic paint is crucial for achieving the desired effects in a painting. Different thickness levels can dramatically alter the texture, transparency, and overall appearance of the artwork. Artists often choose their acrylic thickness based on the specific characteristics they want to emphasize, such as vibrancy, depth, and detail.

Effects of Acrylic Thickness on Artwork

Thin Acrylic Layers

Using thin layers of acrylic paint allows for greater transparency and subtlety in color blending. This technique is particularly effective in creating washes or glazing effects, which can add depth to a painting without overwhelming it. Artists like Zaria Forman utilize thin layers to capture the delicate beauty of icy landscapes in pieces such as “Greenland No. 63”.

Medium Acrylic Thickness

Medium thickness acrylics strike a balance between opacity and transparency, offering versatility in application. This thickness is commonly used by artists like Kehinde Wiley in works such as “Portrait of a Young Gentleman,” where the combination of detailed portraiture and vibrant backgrounds showcases the benefits of a moderate thickness, allowing for both depth and vibrancy.

Thick Acrylic Application

Thick acrylic layers create bold textures and defined shapes, making them ideal for artists who wish to express intensity and movement. Jenny Saville’s “Ebb and Flow” is an example of how thick applications can convey raw emotion and vulnerability, as the layered acrylic emphasizes the subject’s physicality and presence.