Acrylic Fabrication

Explore comprehensive guides, expert tips, and detailed techniques on custom acrylic fabrication, including cutting, bending, drilling, bonding, and polishing to achieve high-quality acrylic products. Ideal for professionals and DIY enthusiasts alike.

Acrylic Cutting

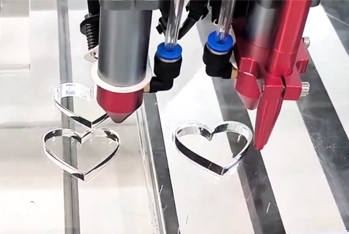

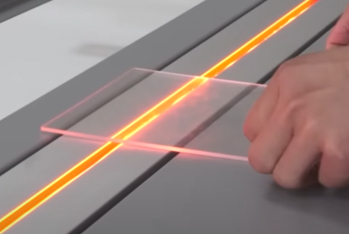

Laser Cutting (CO₂ Laser)

Most precise and clean edge, ideal for intricate designs.

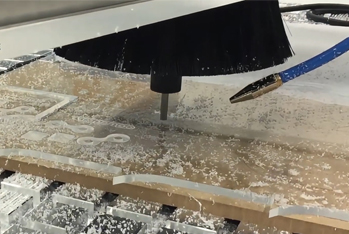

CNC Routing

Good for thicker acrylic and complex 3D shapes.

Saw Cutting

Basic straight cuts for larger sheets.

Drilling

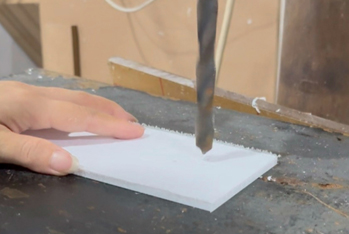

Bench Drill Press

Small to medium batches where accurate hole placement is needed.

Handheld Electric Drill

Highly flexible and portable. On-site work, prototypes, and low-volume custom jobs.

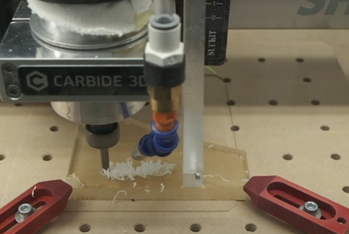

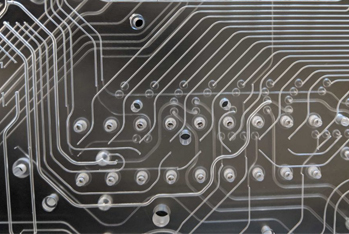

CNC Drilling

Automated, precise, and repeatable. Mass production and complex layouts with consistent hole positions.

Polishing

Flame Polishing

Quick and clean finish on edges using a hydrogen flame.

Buffing/Mechanical Polishing

High-gloss finish using a polishing wheel and compound.

Vapor Polishing

Used for optical clarity, especially in high-end lenses or medical devices.

Bending (Thermoforming)

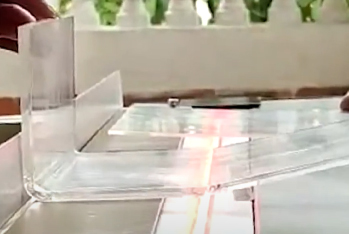

Line Bending

Acrylic is heated along a single line and bent manually.

Oven/Form Bending

The entire sheet is softened and molded into 2D/3D shapes.

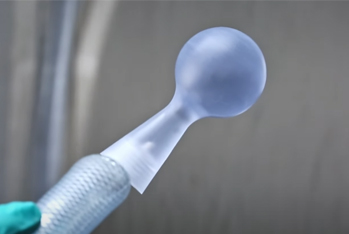

Blow Molding / Drape Forming

Used for rounded or curved surfaces, like helmet visors or display domes.

Bonding (Cementing/Joining)

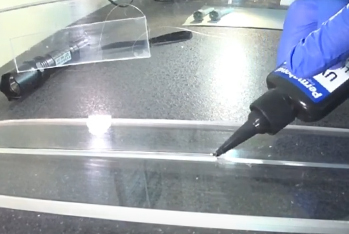

Solvent Cementing

Fuses two pieces chemically with a clean seam.

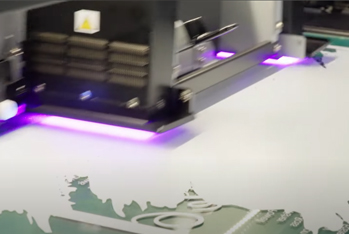

UV Adhesive Bonding

For clear and invisible joints, cured with UV light.

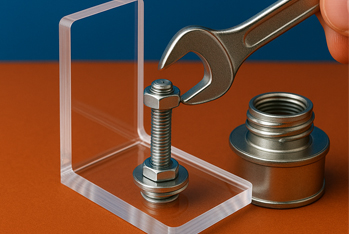

Mechanical Fastening

Screws, bolts—less aesthetic, more for utility.

Surface Finishing & Printing

Screen Printing/UV Printing

For logos, patterns, and labels.

Painting

Requires proper primers and acrylic-compatible paint.

Engraving

Done with laser or rotary tools for decorative/custom text.

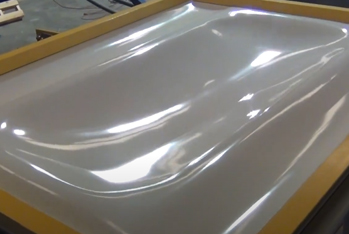

Thermoforming

Vacuum Forming

Fast and cost-effective for medium-depth shapes.

Pressure Forming

Produces sharper details and deeper draws than vacuum forming.

Drape Forming

Often combined with trimming and polishing afterward.

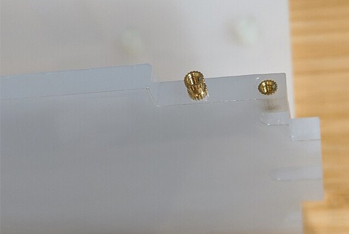

Thread Tapping & Inserts

Direct Tapping

Tap slowly and clear chips frequently to avoid cracking.

Threaded Metal Inserts

A brass or stainless steel insert is embedded into the acrylic using heat or mechanical pressure.

Threaded Inserts

Metal inserts are glued into pre-drilled holes using epoxy adhesive.

Laminating

Film Lamination

Applying a colored, frosted, textured, or protective vinyl film onto the acrylic surface using adhesive and a laminator or squeegee.

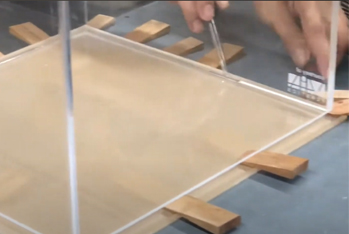

Layer Lamination

Two or more layers of acrylic sheets are bonded together using UV adhesive, solvent cement, or pressure.

Printed Graphic Lamination

A printed image or logo is sandwiched between two acrylic sheets or printed on a backing layer and laminated with clear acrylic.

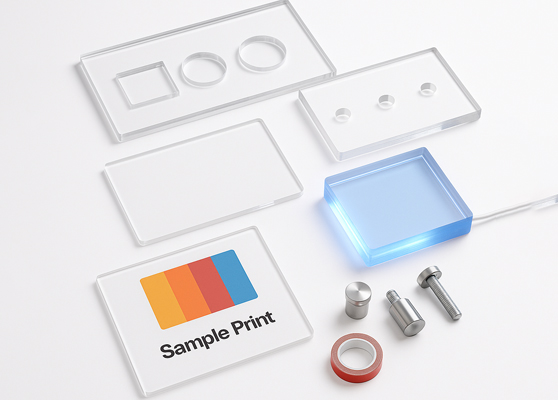

Other Resource

Quick FAQs on acrylic finishes & performance: scratch resistance, UV stability, anti-glare, fire rating, recyclability, weather durability, and lifespan.

Upload vector art, choose thickness & finish, cut shapes, drill holes, add LEDs, pick hardware.

Retail displays, brochure stands, photo frames, menus, awards, and business card holders.

Celebrate client wins with custom acrylic awards highlighting top achievements.