FAQs

Find quick answers to your questions about custom acrylic products, including materials, sizes, finishes, printing, installation, pricing, shipping, and care instructions. Whether you're ordering signs, display stands, or custom-cut panels, this FAQ helps you make informed decisions with confidence.

Acrylic Material Basics

Discover key facts about acrylic: types, thicknesses, strength vs glass, finishes, UV resistance, and custom cutting options—your guide to acrylic basics.

What is acrylic?

Is acrylic the same as glass?

How strong is acrylic compared to glass?

Does acrylic yellow over time?

Is acrylic conductive?

What thicknesses are available?

What types of acrylic do you offer?

2. Extruded acrylic: More affordable and flexible, great for simple signs.

3. Mirrored acrylic: Reflective surface like mirror, up to 75% lighter than glass.

4. Frosted matte or fluorescent: For design accents or diffused lighting.

5. UV-filtering: Blocks up to 95% of UV for photo-sensitive areas.

What thickness tolerances should I expect?

What finishes are available?

Matte/frost: Sandblasted or film-coated for diffusion.

Mirror: Reflective.

Fluorescent/opaque/translucent: Custom hues for design effects.

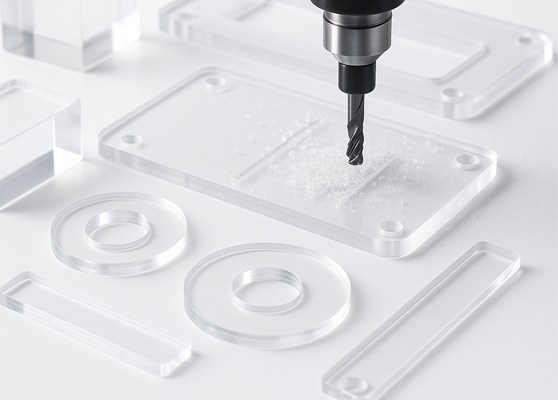

Can acrylic sheets be custom-cut?

Fabrication & Customization

FAQs guide you to prep files, pick cast or extruded acrylic, finish edges, print graphics, drill holes, review proofs, integrate LED, select mounting hardware.

Do you offer contour cuts?

Are edge finishes available?

CNC-polished edges: Glossy, slightly less mirrored.

Raw (laser-cut) edges: Slightly frosted, ideal for diffusing LED lights.

Can I choose between cast and extruded acrylic?

Is mirrored or colored acrylic offered?

How is printing done on acrylic?

Can I print on both sides?

Are LED/backlit acrylic signs available?

Can you create back-to-back signs?

Do you offer drilled holes?

Is hole-drilling included?

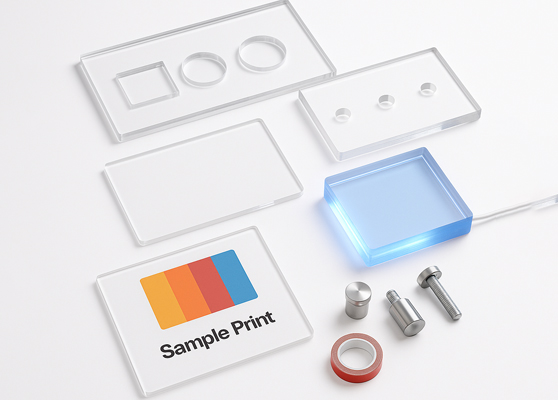

What mounting options exist?

Spacers (standoffs) in stainless steel, brass, or aluminum in sizes ⅜″, ½″, ¾″, and 1″.

3M VHB double-sided tape.

Concealed wall magnets.

Wall anchors/screws as needed.

Can I do dimensional lettering?

What design file types are accepted?

Do you provide proofs?

What’s the max/min sign size?

Maximum per piece: 96″ × 48″. Larger items are built by bonding or shipped panelized.

Installation & Mounting

Find quick answers on installing and mounting acrylic products: tools, drilling templates, no-drill adhesives, hardware options, alignment tips, and removal.

How do I install standoff-mounted signs?

2. Drill holes and insert anchors.

3. Screw barrel into anchors.

4. Hang sign on studs, finalize with caps.

What tools do I need?

Can I install without drilling?

Best hardware for rough surfaces?

Can I drill holes myself?

How do I hang letters?

Any support for large signs?

Can I use zip-ties or string?

Do you offer installation templates?

What anchors are included?

How am I protected?

Can I remove signs later?

Ceiling-mounted or hanging installation?

How do I align double-sided signs?

Can signs be bent for curved surfaces?

Cleaning & Maintenance

Quick cleaning & care tips for acrylic: approved soaps, scratch polish, UV protection, proper storage, warp prevention, safe disinfection, & hardware check‑ups.

How do I clean acrylic signs?

Can I use glass cleaner?

Got scratch-resistant options?

Will UV degrade my sign?

How do I store acrylic?

Can signs warp?

How do I fix minor scratches?

Are hardware parts durable outdoors?

How to maintain LED edge-lit signs?

Can adhesive tape lose grip?

What about painting or coating acrylic?

Can I engrave existing signs?

How do I disinfect signs?

What’s the lifespan of my sign?

Can hardware be replaced later?

Design & Customization Deep-Dive

Detailed answers on design choices: file formats, cast vs extruded, edge finishes, color options, printing methods, LED integration, proofs, and bonding.

What file format should I submit for custom-cut designs?

How do I choose between cast and extruded acrylic?

2. Extruded acrylic: Thinner, more flexible, cost-effective for short-run or budget projects. Choose based on budget, intended lifespan (outdoor vs. indoor), and visual clarity needs.

Can I create 3D lettering with standoffs included?

What edge‑polishing options are there and how do they differ?

2. CNC-polished edge: Near-flame quality, more affordable.

3. Raw edge (laser-cut): Matte, slightly frosted; excellent for diffusion on illuminated pieces.

How do I specify mounting hardware?

Can I choose frost or colored edges?

Do you offer matte or anti-glare surface finishes?

Can I order acrylic that filters UV or is shatter-resistant for pool signage?

Can my design include internal lighting grooves?

Do you provide proofing for LED placement?

What about painting or coating acrylic?

Can I have rounded corners or slots cut into my signs?

Is reverse (back) printing possible?

How accurate is the color match between print and my brand guidelines?

Can you laminate two sheets together for sandwich signs?

What are minimum size limitations for small acrylic items?

For 3 mm: min 15 mm wide/long

For 6 mm: min 20 mm wide/long Anything smaller risks cracking during cutting—our system flags problematic sizes during proofing.

Production & Lead Times

Quickly learn acrylic production details: standard and rush lead times, proofing steps, revision policies, volume pricing tiers, shipping methods, and real‑time order tracking.

What is the typical lead time for custom acrylic signs?

2. Large or intricate pieces: 7–10 days.

3. LED/backlit signage: Up to 15 days due to lighting assembly and testing. Rush orders available—ask for a quote based on current workload.

Can you expedite rush orders or same-day fabrication?

How do you handle order proofing and corrections?

What happens if my proof is delayed?

Are there quantity discounts or tiered pricing?

Do you keep orders and specs on file for reorders?

Are shipping costs included?

Do you ship internationally?

What packaging methods do you use for shipping?

What if pieces arrive damaged?

Pricing & Cost Factors

Find clear answers on acrylic pricing: material types, thickness impacts, volume discounts, setup fees, printing & drilling costs, hardware charges, taxes, and shipping factors.

How is pricing calculated for custom cuts and printing?

Does printing on both sides cost extra?

What is the cost difference between cast and extruded acrylic?

Is there a setup fee for CNC cutting?

How are drilling and standoffs priced?

Do you charge for proofs?

Are there minimum order values?

Can I get a quote before submitting a file?

Do taxes apply?

What payment methods do you accept?

Finishes & Performance

Quick FAQs on acrylic finishes & performance: scratch resistance, UV stability, anti-glare, fire rating, recyclability, weather durability, and lifespan.

Are sign surfaces scratch-resistant?

Do you offer anti-glare or matte coatings?

Will ink fade in sunlight?

Can large panels bow or warp outdoors?

Is the product flame retardant?

Are materials recyclable?

Can I use the product in a restroom or high-humidity area?

Can you pre-drill for electrical conduit or wiring?

Are acrylic signs food-safe?

Do you warranty your products?

Other Resource

Quick FAQs on acrylic finishes & performance: scratch resistance, UV stability, anti-glare, fire rating, recyclability, weather durability, and lifespan.

Upload vector art, choose thickness & finish, cut shapes, drill holes, add LEDs, pick hardware.

Retail displays, brochure stands, photo frames, menus, awards, and business card holders.

Cut, polish, and bond acrylic panels into precise custom parts using CNC, laser, and drills.

Celebrate client wins with custom acrylic awards highlighting top achievements.