Table of Contents

If you’ve ever watched a rare figure, signed card, or limited-edition gadget slowly collect dust (or worse, get scratched during “just a quick wipe”), you already know the problem: collectibles don’t stay collectible on their own. They need a clean, clear, tough display setup that looks premium and behaves like protective packaging.

That’s why acrylic display boxes show up everywhere—from sneaker drops and anime figures to museum-style collectibles and retail counter displays. And if you’re buying for a brand, a retailer, a wholesaler, or an OEM program, acrylic boxes also help you standardize presentation and keep your rollout smooth.

We build custom acrylic solutions as an Acrylic Fabrication Manufacturer in China for bulk orders, OEM/ODM projects, and wholesale buyers.

Acrylic Light Transmission and Clarity

Acrylic is known for high clarity. Many published material specs list visible light transmission around 92% for clear acrylic (grade-dependent). In plain terms, that means your item looks sharp—clean edges, true colors, less “cloudy panel” effect.

This matters in real life because people buy with their eyes:

- A collector sees paint details on a figure’s face.

- A shopper can read tiny print on a trading card label.

- A retail team gets fewer “Is that used?” questions caused by hazy covers.

If you need a consistent look across SKUs, you can also match sheet grade and thickness using custom acrylic sheets as your baseline material.

UV Protection for Collectibles

Sunlight looks great in a room. UV damage doesn’t.

UV can fade inks, yellow some plastics, and dull finishes over time. UV-filtering acrylic options can block a large share of UV (specs vary by brand and grade, and some list up to ~99% UV blocking in defined UV ranges). If you display collectibles near windows, store entrances, or bright lighting, UV-filter acrylic is the quiet upgrade that helps you protect value.

Practical scenarios where UV filtering pays off:

- Signed posters and photos in a shop wall display

- Limited edition packaging with bold printed colors

- Vintage paper items in a collector’s home office

Impact Resistance and Safer Handling

Glass looks classy until it chips or shatters during restocks, trade shows, or shipping. Acrylic is widely recognized as more impact resistant than standard glass. That’s a big deal for:

- Retailers who move displays every season

- E-commerce sellers who ship fragile collectibles

- Wholesalers who stack cartons and can’t babysit every drop risk

If your team runs fast-paced ops, acrylic reduces “oops moments” that turn into returns and write-offs.

Lightweight Display Boxes for Shipping and Merchandising

Acrylic often comes in at roughly about half the weight of glass in similar use cases. That makes daily handling easier and reduces fatigue for store staff. It also helps when you’re planning bulk logistics—lighter parts simplify picking, packing, and warehouse moves.

For brands tracking rollout speed, this shows up as cleaner TSM (time-to-shelf). When displays arrive intact and are easy to place, you don’t lose days to replacements, rework, or messy installs.

If you’re building a full display kit (box + riser + signage), you can bundle components through custom acrylic displays to keep everything consistent.

Anti-Reflective Acrylic and Store Lighting

Ever tried to photograph a collectible through a shiny cover? You end up capturing the ceiling lights, not the product.

Anti-reflective acrylic options can reduce reflections dramatically (some published specs list reflection under a couple percent for coated products). That helps in two places where glare kills conversion:

- Retail: overhead LEDs, spotlights, glossy packaging

- E-commerce: product photos, live streams, short-form video

If you sell collectibles online, fewer reflections means fewer reshoots and cleaner content. That’s a real workflow win.

Anti-Static Acrylic for Dust Control

Dust is the enemy of “premium.” Regular acrylic can attract dust due to static charge, especially in dry environments. Anti-static acrylic options help reduce that cling.

What you get:

- Less dust magnet behavior on the inside walls

- Fewer wipe-down cycles for store staff

- Cleaner unboxing and better “fresh out of the box” vibes

If your collectible is fabric-heavy (plush, textile parts) or has micro details (miniatures), dust control is not a nice-to-have—it’s part of the display spec.

Abrasion-Resistant Coatings and Cleaning

Here’s the honest part: acrylic can scratch if you clean it like glass.

If your display sits in a high-touch zone—checkout counter, showroom table, convention booth—abrasion-resistant coated acrylic options help reduce the “swirl marks” that show up after frequent wiping.

Simple best practices your ops team will appreciate:

- Use microfiber (not paper towels)

- Avoid harsh cleaners

- Train staff to wipe gently, not grind dust into the surface

That’s how you keep displays looking new without babysitting them.

Dustproof Storage and Everyday Protection

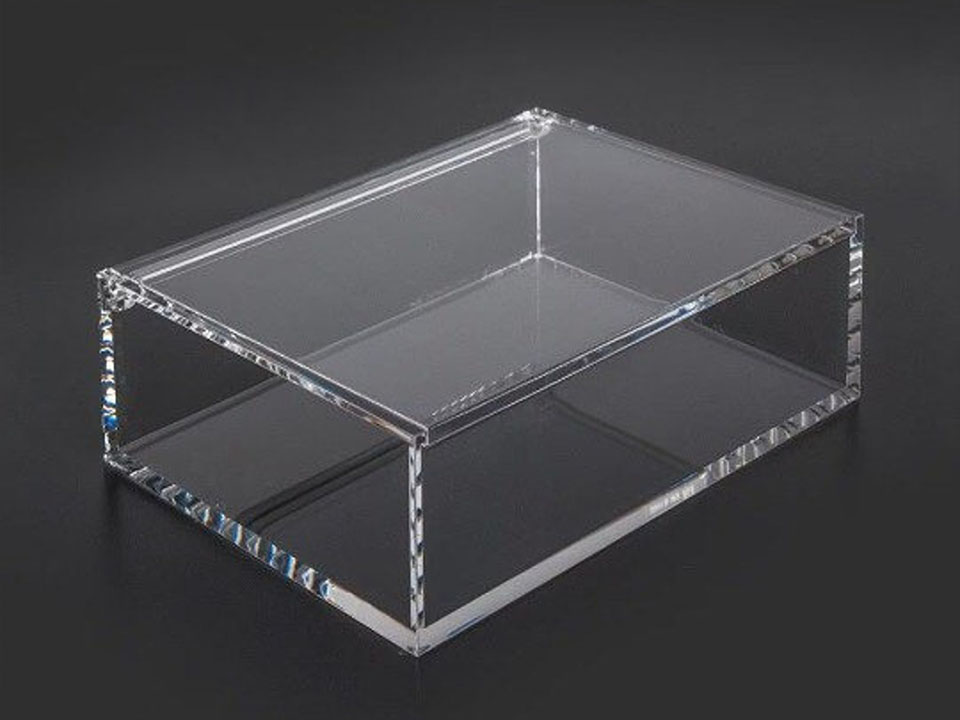

Acrylic boxes don’t just “look nice.” A closed design blocks dust, reduces fingerprints, and discourages casual handling.

This is the everyday protection story:

- You stop people from touching the item “just to feel it”

- You cut down on shelf grime

- You keep the collectible ready for photos, resale, or audits

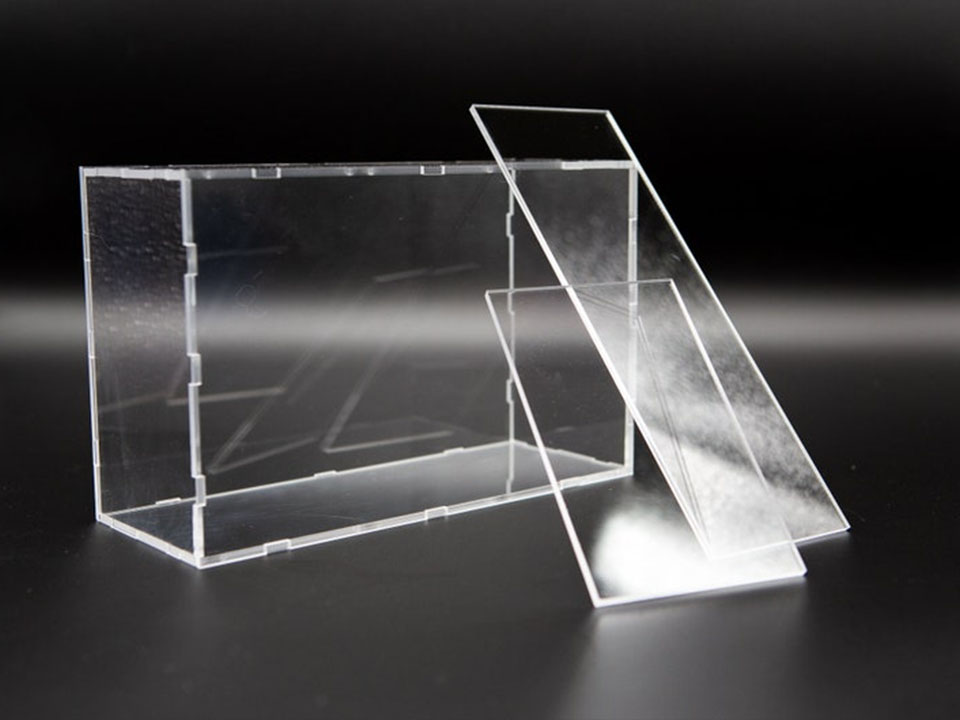

If you need a practical, protective form factor, start with custom acrylic boxes and tune the details (lid style, ventilation, thickness, locking, foam base).

Custom Acrylic Fabrication for OEM/ODM Programs

Collectors love one-offs. Businesses need repeatability.

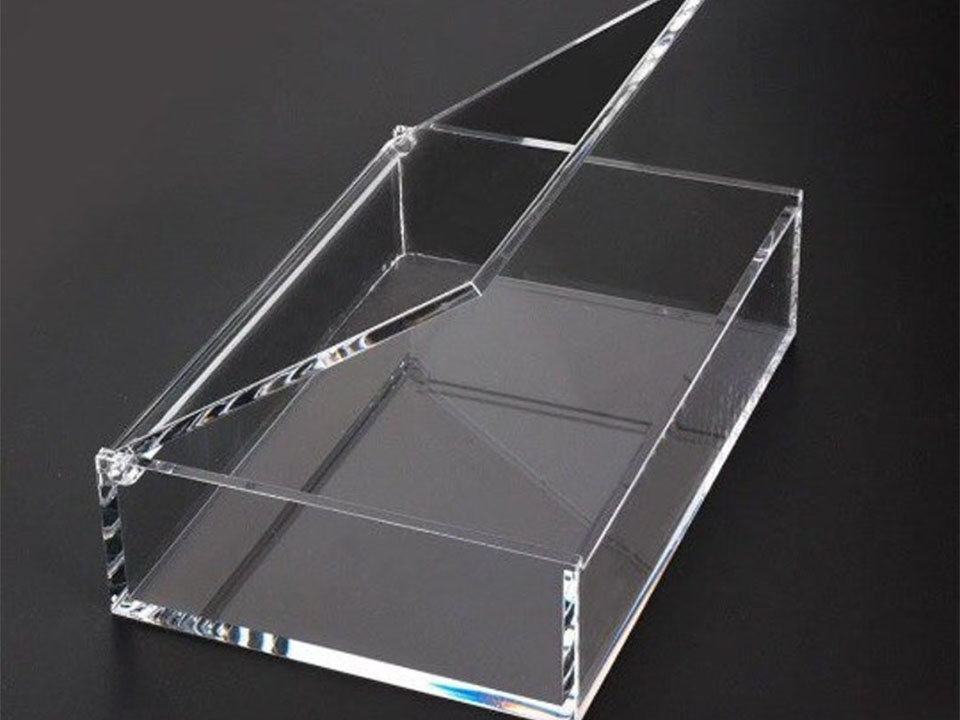

For OEM/ODM buyers, acrylic boxes work well because you can dial in:

- Fit and tolerances (snug without stressing the item)

- Edge finish (polished edges for a premium look)

- Assembly method (solvent bonding, mechanical fasteners, magnets)

- Branding (UV print, laser engraving, logo plates)

If your product line uses tubes, risers, or structural parts, you can also source material components like custom acrylic rods and tubes for a consistent build.

And when you’re scaling to bulk, QC discipline matters more than marketing copy. If you’re vetting suppliers, check their inspection approach and defect controls under quality control.

Performance Snapshot for Acrylic Display Boxes

Below is a quick “spec-style” summary you can reuse in buyer decks. Values vary by acrylic grade and coating, so treat this like a starting point for your RFQ.

| Feature | Typical published spec range | What it solves | Where it matters most |

|---|---|---|---|

| Light transmission | ~92% (clear acrylic, grade-dependent) | Keeps details crisp | Cards, figures, premium packaging |

| UV filtering (UV-grade acrylic) | Up to ~99% (range-dependent) | Slows fading/yellowing | Posters, photos, colored packaging |

| Impact resistance | Higher than standard glass | Reduces break risk | Retail ops, shipping, events |

| Weight vs glass | Often ~50% lighter | Easier handling and logistics | Bulk rollouts, store resets |

| Reflection (AR acrylic) | Low-reflection coatings available | Cleaner viewing + photos | Retail lighting, e-com content |

| Anti-static option | Available by grade/coating | Less dust cling | Dry climates, detailed items |

| Abrasion-resistant coating | Available by product line | Fewer cleaning scratches | High-touch counters, showrooms |

Real-World Display Scenarios That Sell More

| Scenario | The pain point | Acrylic box setup that works |

|---|---|---|

| Countertop “impulse zone” near checkout | Shoppers bump items, staff cleans constantly | Thick clear box + abrasion-resistant option + simple lift-off lid |

| Limited drop launch wall | UV + glare makes packaging look tired | UV-grade + anti-reflect option for clean photos |

| E-commerce studio photos | Reflections and dust ruin shots | Low-reflect panel + anti-static option |

| Convention booth | Fast setup, high traffic, lots of handling | Impact-resistant box + lightweight modular risers |

| Collector shelf at home | Dust and sunlight over time | Closed box + UV-grade panel near windows |

How to Order Acrylic Boxes Without Headaches

If you’re buying wholesale, you already know the traps: vague specs, inconsistent polishing, surprise yellow tint, lids that don’t sit flat. Skip the back-and-forth and lock the details early.

A clean RFQ checklist:

- Internal dimensions (what must fit, plus clearance)

- Acrylic thickness and grade (clear, UV-grade, anti-static, AR)

- Edge finish requirement (polished vs standard)

- Lid style (lift-off, hinged, magnetic, sliding)

- Branding method (print, engraving, logo plate)

- Packing standard for bulk shipment (scratch protection)

If you want a guided path, use how to customize to align specs before sampling. When you’re ready to kick off, reach out via contact and include your target use case (retail, e-com, wholesale, OEM).

Acrylic display boxes don’t just protect collectibles. They help you control presentation, reduce handling damage, and keep your rollout clean—especially when you’re scaling across stores, marketplaces, or distributor channels.